TR1 Manual

Edit this on GitLab

TR1 Measurement & Simulation Modules Thermocouple and RTD Measurement

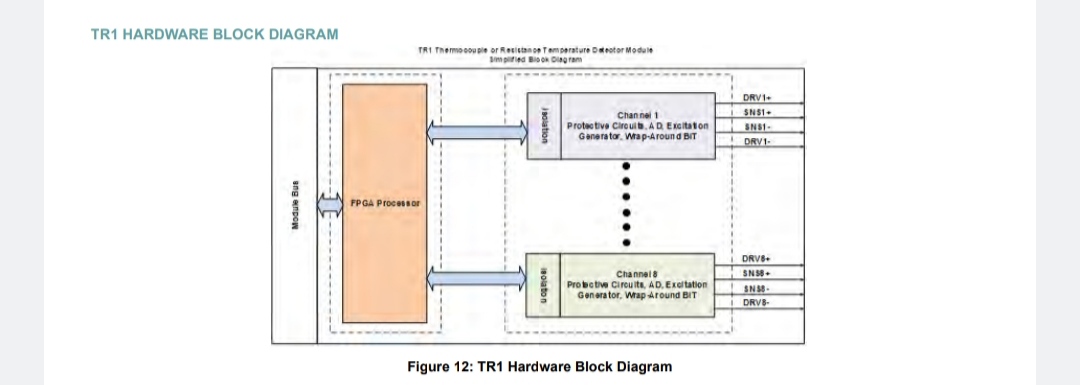

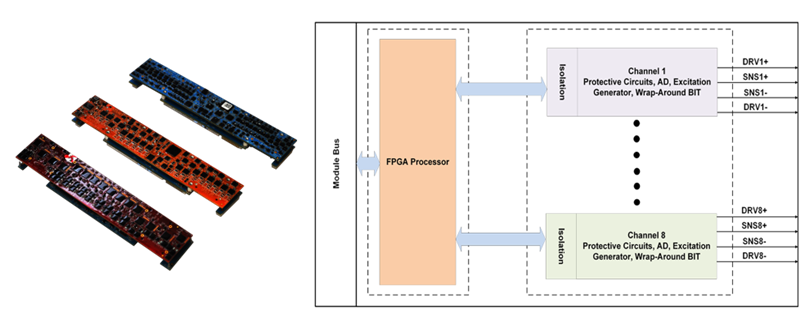

The TR1 provides 8 channels which can be individually programmed as a Thermocouple (TC) or a Resistance Temperature Detector (RTD) measurement interface. When configured as a TC, the channel can interface with virtually all thermocouple-type NIST temperature ranges. When configured as an RTD, the channel can interface to two, three and four-wire platinum RTD sensor configurations. The TR1 channels are individually configurable for up to 8 isolated TC or low-voltage range A/D measurement channels. Configuration programmability provides interfaces for industry standard NIST thermocouple types (J, K, T, E, N, B, R, and S). The TR1 channels are individually configurable for up to 8 isolated RTD measurement channels. Each channel is configurable for use with 4-wire, 3- wire or 2-wire connections to the RTD sensors. All RTD channels provide measurement results in Single Precision Floating Point Value (IEEE-754) format.

FEATURES

-

Thermocouple Measurement

-

Interfaces with most standard NIST thermocouple types (J, K, T, E, N, B, R, and S)

-

Self-powered

-

Large temperature range; up to 2300° C

-

Accuracy up to ±0.2° C (thermocouple type dependent)

-

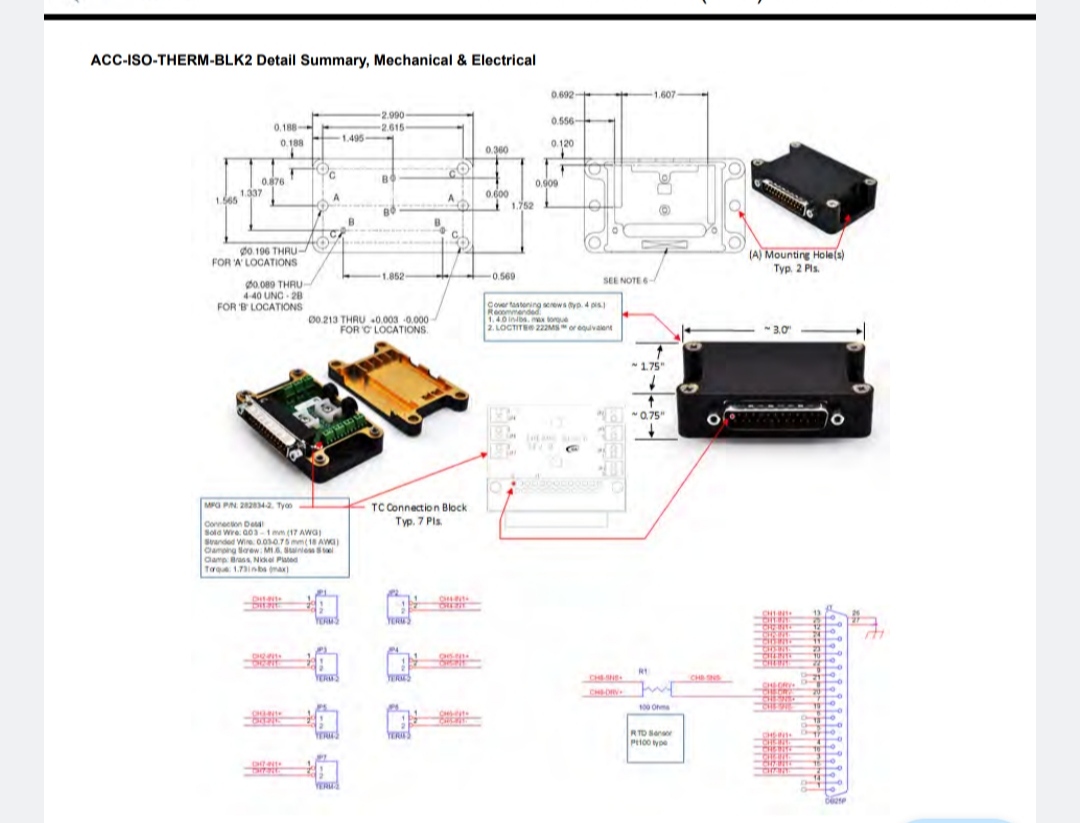

Thermo-block compensation option P/N ACC-ISO-THERM-BLK2 (If accessory used, channel 8 is automatically allocated as an RTD interface for the thermo-block compensation temperature measurement)

-

-

RTD Measurement

-

Higher accuracy and repeatability as compared with thermocouples in applications below 600 °C

-

Two, three or four-wire mode

-

Single Precision Floating Point Value (IEEE-754) format

-

Open sensor connections are detected and reported

-

1 mA, 500 µA, 250 µA & 100 µA excitation sources for Pt100, Pt500, Pt1000 and Pt2000 ranges

-

-

Independently Programmable

-

Up to 8 RTD channels

-

Up to 8 Thermocouple channels

-

-

Independent Mode Select

-

Configures Thermocouple or RTD

-

-

Programmable Sample Rate

-

Sets the sampling rate of the A/D

-

-

Offset Temperature

-

Provides ability to null for any system induced measurement errors

-

SPECIFICATIONS

Thermocouple

A/D Converter |

Independent 24-bit Sigma-Delta type (one for each channel) |

Temperature Range |

NIST temperature range (J, K, T, E, N, B, R, S thermocouple types) |

Voltage Measurement Range |

±78.125 mV to an accuracy of ± 25 µV over operational temperature. |

Overvoltage Input Tolerance |

± 4 V continuous, ±50 V momentary duration limited to 100 ms (applied at signal input) |

50/60 Hz Noise Rejection |

>70 dB |

CMR |

85 dB (minimum) |

Differential Input Impedance |

>10 KΩ |

Digital Output |

IEEE 754-2008 (binary32) programmable for ° C, ° F (programmed for temperature), 24-bit (signed), based on % FSR (±78 mV) (programmed for A/D) |

Accuracy |

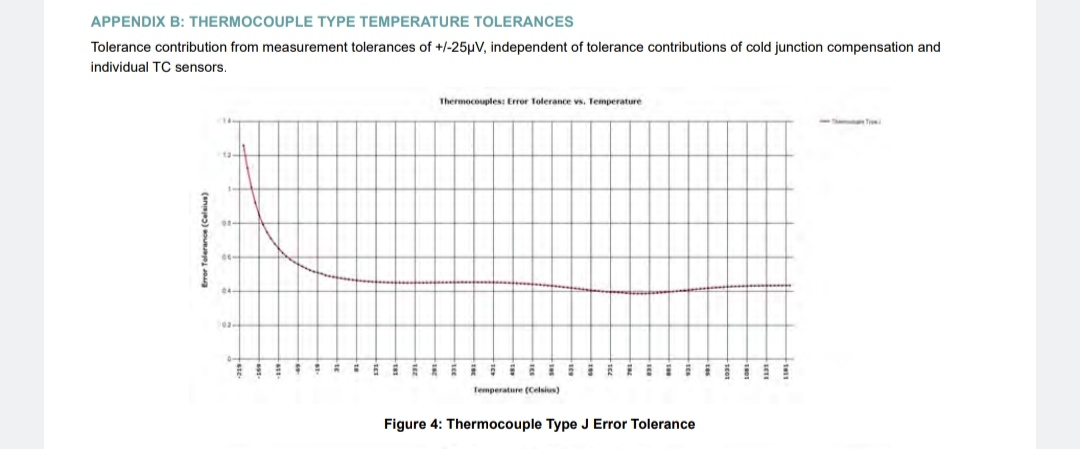

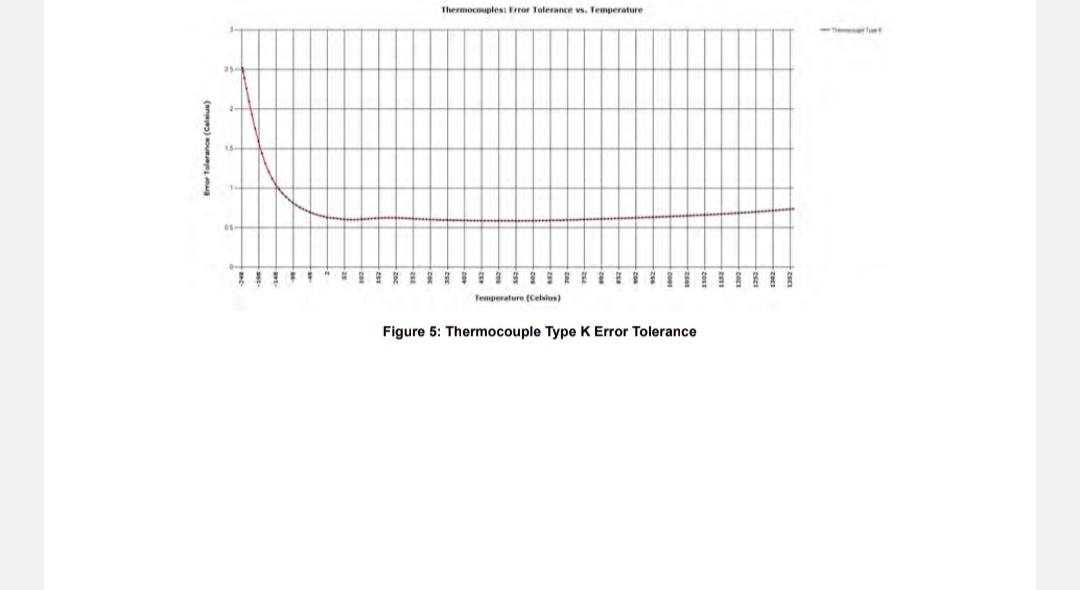

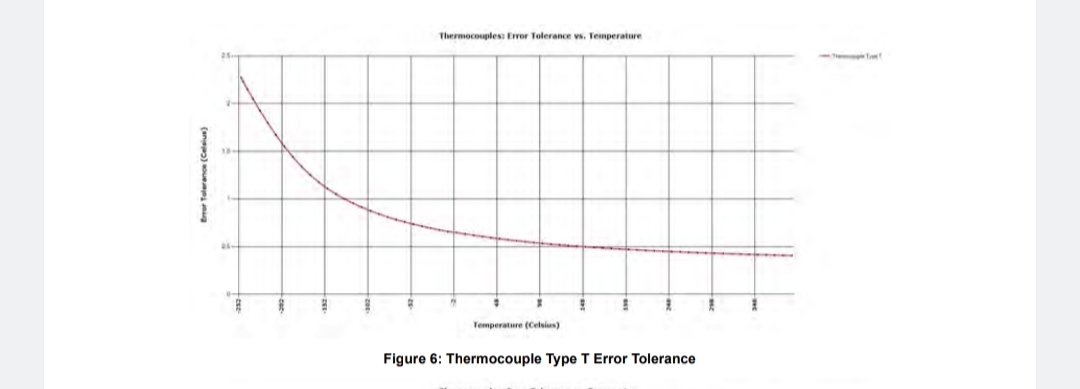

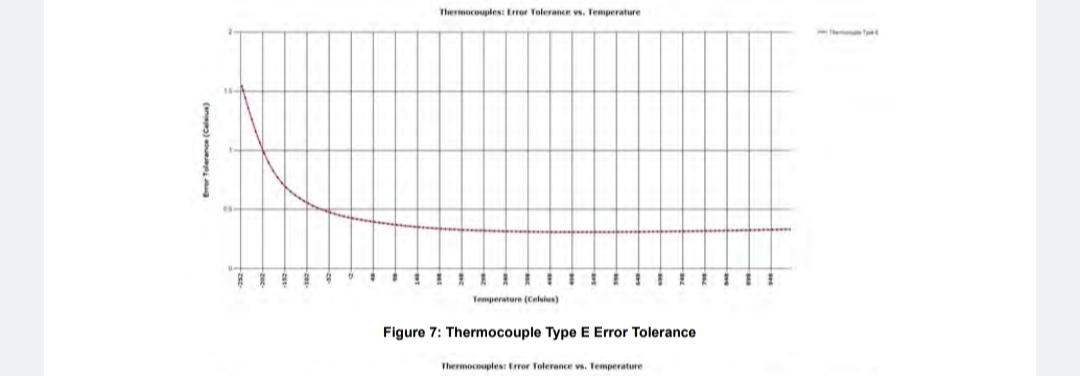

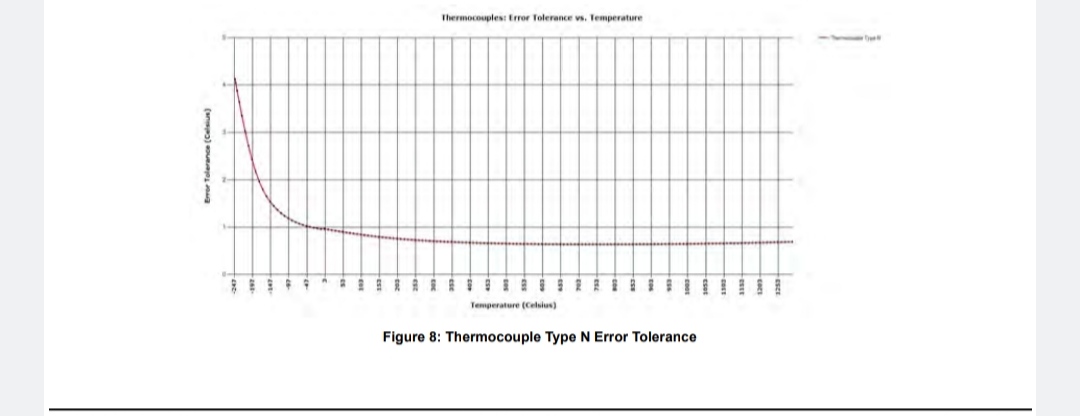

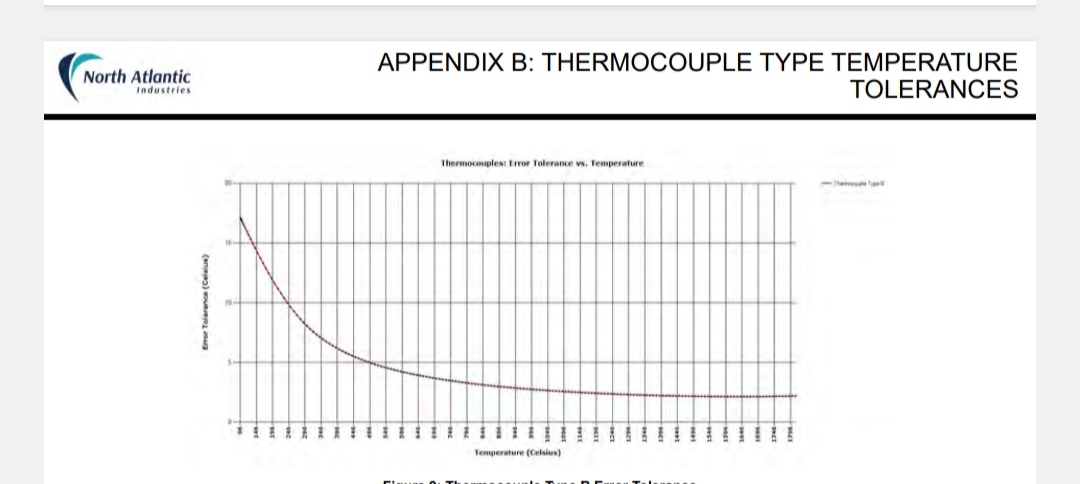

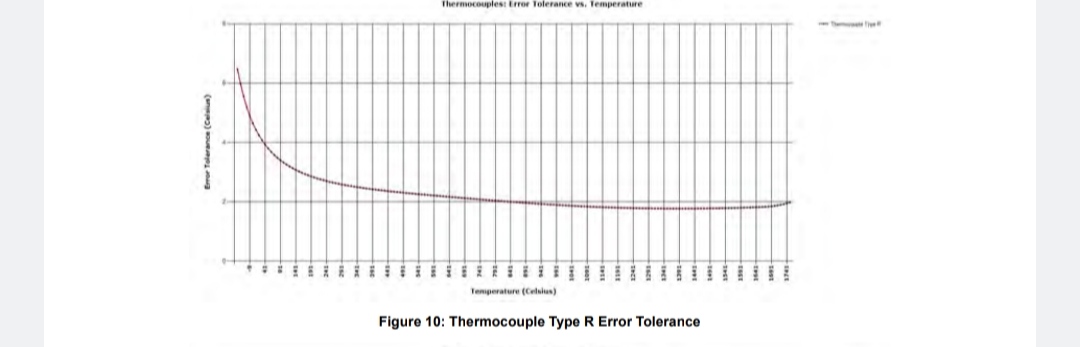

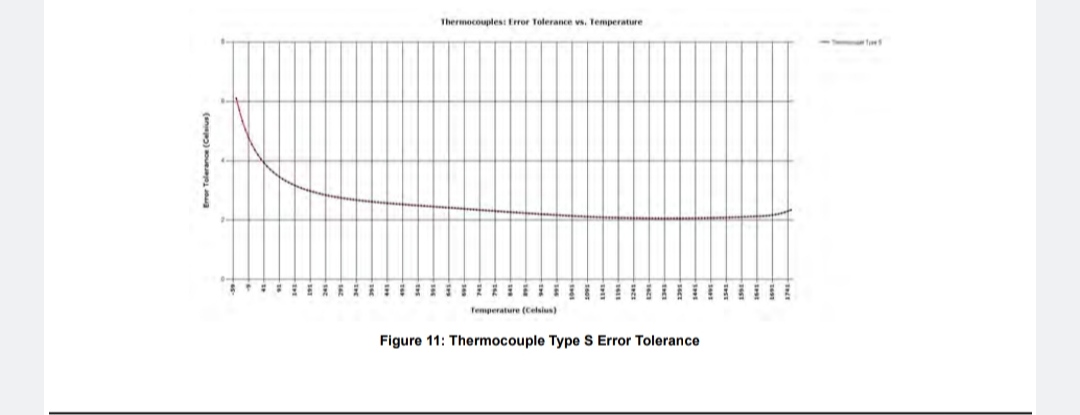

Based on minimum update rate and w/thermocouple block I/F compensation; ±0.2° C (Type J/N), ±0.3° C (Type K), ±0.3° C (Type T/E), ±0.3° C (Type R/S), ±0.9° C (Type B), ± 0.2% FSR (programmed for raw A/D digital output) Resolution 0.01° typ. (programmed for temperature, thermocouple selection dependent) |

Sample Rate |

Programmable between 3-4800 Hz |

Thermo-Block Interface |

Optional thermocouple interface for connection of up to 7 thermocouple sensors. Pt100 RTD sensor for cold junction compensation temperature. |

Build-In-Test (BIT) |

Continuous background ‘online' accuracy, OPEN detection capability. |

RTD

Analog Input Resolution |

24 bits per channel |

RTD Interface |

4, 3, or 2-wire RTD interface capability. Specifically designed for use with common 100 Ω, 500 Ω, 1000 Ω and 2000 Ω RTDs with general resistance measurement capability up to 8000 Ω. Direct readout of temperature in ° C / ° F with standard Pt sensors. |

Open Line Detection |

Ability to detect an open in any line or RTD in all wire modes. |

Excitation |

1mA (Pt100), 500µA (Pt500), 250µA (Pt1000) or 100µA (Pt2000) for 2- & 4-wire mode; 500µA (Pt100), 250µA (Pt500), 125µA (Pt1000) or 50µA (Pt2000) for 3-wire mode |

Accuracy |

±0.1% of full-scale value @ 5 samples per second (4-wire mode only), ±0.2% of full-scale value @ 5samples per second (3-wire mode only), ±1.2% of full-scale value @ 5 samples per second (2-wire mode only) |

Sample Rate |

Programmable between 3-4800 Hz |

Output Format |

Resistance/Temperature |

Built-In-Test (BIT) |

Continuous background 'online' accuracy, OPEN detection capability. |

General

Power |

+5 VDC @ 480 mA typ. |

Ground |

Independent channels; isolated from system ground. |

Weight |

1.5 oz. (42 g) |

ESD Protection |

Designed to meet the testing requirements of IEC 801-2 Level 2. (4 kV transient with a peak current of 7.5 A and a Tc of approximately 60 ns) |

Number of Channels |

Eight channels programmable for RTD or Thermocouple mode. |

Input Interface |

Independent differential input channels. |

Architected for Versatility

Edit this on GitLab

NAI’s Configurable Open Systems Architecture™ (COSA®) offers a choice of over 100 smart I/O, communications, or Ethernet switch functions, providing the highest packaging density and greatest flexibility of ruggedized embedded product solutions in the industry. Preexisting, fully-tested functions can be combined in an unlimited number of ways quickly and easily.

One-Source Efficiencies

Eliminate man-months of integration with a configured, field-proven system from NAI. Specification to deployment is a seamless experience as all design, state-of-the-art manufacturing, assembly and test are performed - by one trusted source. All facilities are located within the U.S. and optimized for high-mix/low volume production runs and extended lifecycle support.

Product Lifecycle Management

From design to production and beyond, NAI’s product lifecycle management strategy ensures the long-term availability of COTS products through configuration management, technology refresh and obsolescence component purchase and storage.

INTRODUCTION

As a leading manufacturer of smart function modules, NAI offers over 100 different modules that cover a wide range of I/O, measurement and simulation, communications, Ethernet switch, and SBC functions. Our TR1 smart function module provides 8 channels which can be individually configured as a Thermocouple (TC) or Resistance Temperature Detector (RTD) measurement interface. This user manual is designed to help you get the most out of our Thermocouple/RTD smart function module.

TR1 Overview

NAI’s TR1 module offers a range of advanced features tailored to meet the demands of precision measurement applications, both in Thermocouple mode and RTD mode, including the following:

Thermocouple Features

NIST Thermocouple Interface Capability: In thermocouple mode, the TR1 module features configuration programmability which provides interfaces for all standard NIST thermocouple types (J, K, T, E, N, B, R, and S), providing unparalleled versatility in thermocouple compatibility.

Self-Powered: One standout feature of the thermocouple mode is its self-powered functionality, eliminating the need for external power sources and simplifying installation. This not only streamlines the setup process but also enhances its suitability for a wide range of applications.

Large Temperature Range: The thermocouple function boasts an expansive temperature measurement range, reaching a remarkable 2300⁰C. This exceptional range makes it well-suited for applications where extreme temperatures are encountered, such as jet engines and gas turbine exhaust.

Up to ±0.2⁰C Accuracy: With thermo-block compensation, the thermocouple provides compensated measurements at accuracies up to ±0.2⁰C.

Optional Thermo-Block Compensation: NAI offers an optional accessory (ACC-ISO-THERM-BLK2) which connects to the thermocouple sensors, allowing for automatic cold junction compensation temperature through an onboard RTD temperature sensor (CH8 will automatically configure to RTD mode if this accessory is used).

RTD Features

Higher Accuracy and Repeatability: The TR1’s RTD mode excels in accuracy and repeatability when compared to thermocouples, making it an ideal choice for applications with operating temperatures below 600°C. This characteristic ensures that critical measurements are obtained with the utmost precision.

Wire Modes: The module provides flexibility with two, three, or four-wire modes, allowing users to adapt to various measurement setups and requirements, enhancing versatility in different scenarios.

Data Format: The TR1 module utilizes the Single Precision Floating Point Value (IEEE-754) format for data representation, enabling compatibility and ease of integration with other systems and equipment.

Open Sensor Detection: When configured for RTD mode, the TR1 module is equipped with a built-in feature to detect and report open sensor connections. This safeguards against inaccurate measurements caused by sensor failures, promoting data integrity.

Excitation Sources: To accommodate various RTD ranges when configured for RTD mode, the TR1 provides excitation sources of 1 mA (Pt100), 500 μA (Pt500), 250 μA (Pt1000), and 100 μA (Pt2000) for 2- & 4-wire modes, and 500 μA (Pt100), 250 μA (Pt500), 125 μA (Pt1000), and 50 μA (Pt2000) for 3-wire mode. This feature ensures precise measurements across a wide range of applications.

General Features

Independently Programmable: The TR1 module offers the capability to independently program up to 8 RTD or Thermocouple channels. This feature is invaluable for engineers working on complex systems with multiple measurement points, allowing for tailored configuration and control.

Programmable Sample Rate: Users can set the sampling rate of the analog-to-digital converter (A/D) to match the specific needs of their application. This programmable sample rate ensures that data acquisition is optimized for accuracy and efficiency.

Offset Temperature: The offset temperature feature provides users with the means to nullify system-induced measurement errors. This is crucial in achieving the highest level of measurement precision and reliability, especially in critical applications where accuracy is paramount.

PRINCIPLE OF OPERATION

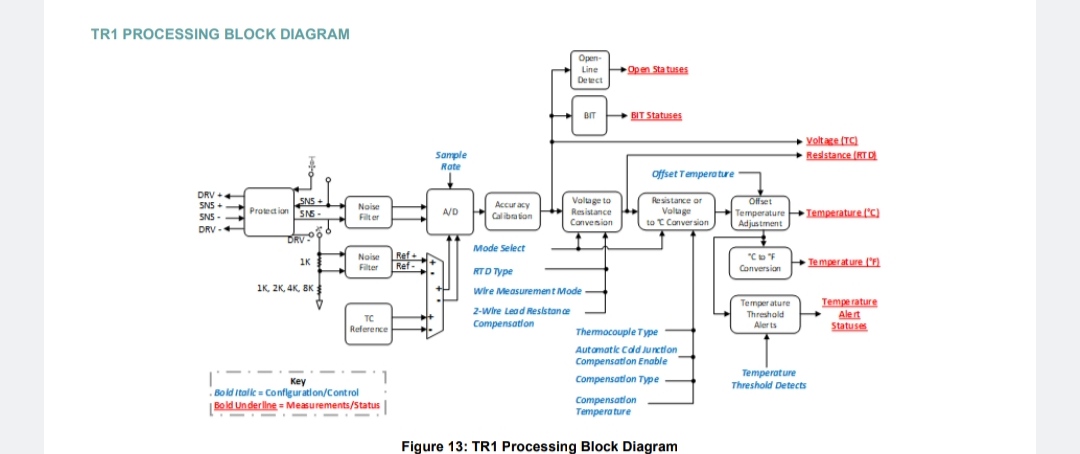

The TR1 is programmable for either Thermocouple or RTD measurement via the Mode Select register.

Thermocouple Capability

While in thermocouple mode, the TR1 provides up to eight individual isolated thermocouple or low-voltage range A/D measurement channels. Configuration programmability provides interfaces for industry standard NIST thermocouple types (J, K, T, E, N, B, R, and S).

Thermocouples are widely used temperature-measurement devices because of their ruggedness, repeatability and fast response time. They offer a cost-effective means for measuring a much wider range of temperatures in comparison to other common solutions like resistance temperature devices (RTD), thermistors, or temperature-sensing integrated circuits (ICs). Although thermocouples can be used over a wider range of temperatures than RTDs and temperature-sensing ICs, they are far less linear. Also, RTDs and temperature-sensing ICs typically offer better sensitivity and accuracy. Thermocouple signals are very low-level and often require amplification or a high-resolution data converter to process the signals. Despite these disadvantages, overall cost, ease of use, and wide temperature range make thermocouples popular.

Thermocouples are constructed with two wires made from dissimilar metals. One wire is predesignated as the positive side, and the other as the negative. The industry standard NIST thermocouple types are defined by the metals or alloys used and the temperature range allowed for each type. Each thermocouple type offers a unique thermoelectric characteristic over its specified temperature range.

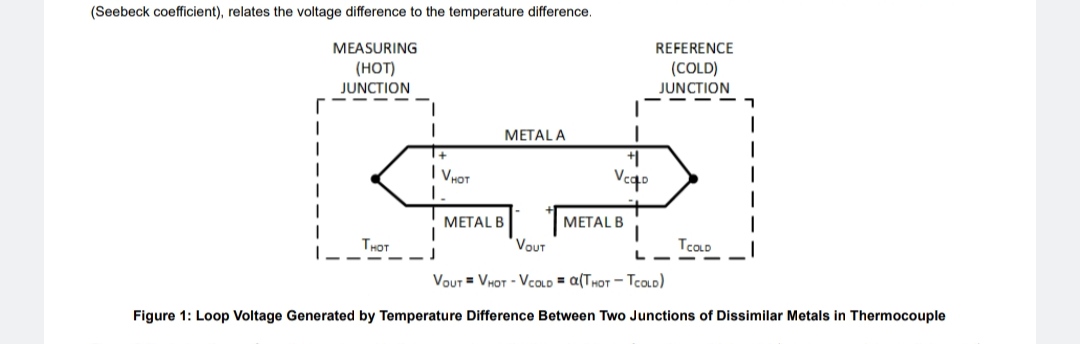

In Figure 1, the voltage generated by the loop is a function of the temperature difference between the two junctions. This phenomenon is known as the Seebeck effect which is described as the process in which thermal energy is converted into electrical energy. The Peltier effect is the opposite of the Seebeck effect which is the process of converting electrical energy to thermal energy. In Figure 1, the measure output voltage (V ) is a function of the difference between the measuring (hot) junction voltage and the reference (cold) junction voltage. Since V and V are generated by a temperature difference between the two junctions, V is also a function of this temperature difference. The scale factor, α (Seebeck coefficient), relates the voltage difference to the temperature difference.

Figure 1. Loop Voltage Generated by Temperature Difference Between Two Junctions of Dissimilar Metals in Thermocouple

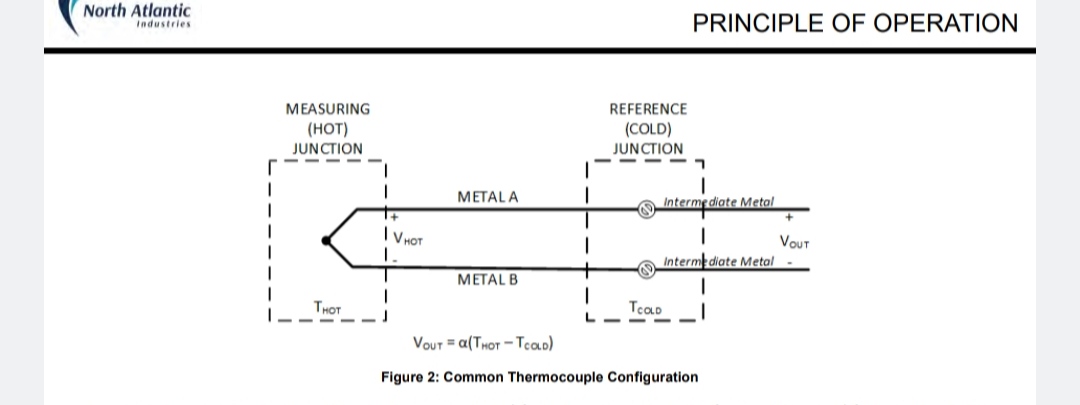

Figure 2 illustrates the configuration most commonly used in thermocouple applications. In this configuration, a third metal (known as an intermediate metal) such as copper, is introduced into the loop and the two additional junctions. In this configuration, provided the two junctions are at the same temperature, the intermediate metal type has no effect on the output voltage. This configuration allows the thermocouple to be used without a separate reference junction. V is still a function of the difference between the hot- and cold-junction temperature, related by the Seebeck coefficient. In this configuration, the cold-junction temperature must be known in order to determine the actual temperature measured at the hot-junction.

Figure 2: Common Thermocouple Configuration

The simplest case occurs when the cold-junction temperature is at 0° C, also known as an ice-bath reference. At T = 0° C, V = V. In this case, the voltage measured at the hot-junction is a direct translation of the actual temperature at that junction.

When the cold-junction temperature is not at 0° C, the temperature of this junction must be known in order to determine the actual hot-junction temperature. The output voltage of the thermocouple must also be compensated to account for the voltage created by the nonzero cold-junction temperature. This process is known as cold-junction compensation.

NAI provides an optional accessory, NAI P/N ACC-ISO-THERM-BLK2, a thermocouple connection interface comprised of a separate isothermal interface/terminal block. The thermocouple sensors are connected to the accessory’s copper measurement wiring harness, allowing for automatic cold junction compensation temperature through an onboard RTD temperature sensor reporting the terminal temperature to a dedicated channel on the module (refer to Appendix A: Optional External Cold Junction Compensation Block Accessory).

|

Note

|

when the configuration for the isothermal interface/terminal block (referred to as Cold Junction Compensation Block) is selected, Channel 8 of the TR1 module will be automatically configured for RTD mode, so this channel cannot be used as a thermocouple channel. |

In lieu of the External Cold Junction Compensation Block Accessory, a user supplied terminal connection block may also be used, provided the terminal temperature is measured and maintained in the manual cold junction compensation temperature register for proper compensation. A benefit of this would be the availability of Channel 8 for an additional Thermocouple or RTD measurement channel.

In addition to cold-junction temperature compensation, the TR1 provides the ability to program temperature offsets, which can be used to null out small temperature deviations from sensors or system interconnections as well as delta measurements from an initial temperature reading. The offset temperature is subtracted from the output temperature reading and may be configured individually for each channel.

The fundamental design of the TR1 is based on independent 24-bit Sigma-Delta A/D converters for each channel. This allows the TR1 to also be used for direct precision low voltage measurements (±78.125 mV) for uses in low-voltage range A/D applications (i.e. shunt resistor voltage/current sense measurements).

TR1 is designed for rugged embedded “on-the-move” or laboratory-grade environments, and provides continuous background built-in-test (BIT) capabilities for accuracy and “open” detection monitoring and flagging.

RTD Capability

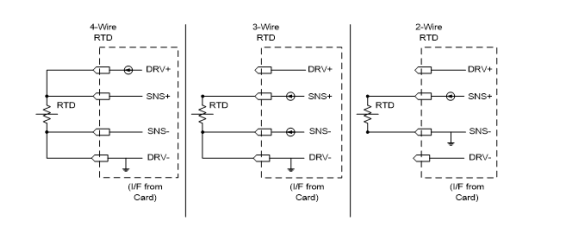

The TR1 channels are individually configurable for up to 8 RTD measurement channels. Each channel is configurable for use with 4-wire, 3-wire or 2-wire connections to the RTD sensors. All RTD channels are calibrated at the factory and measurement results provided in Single Precision Floating Point Value (IEEE-754) format.

Open sensor connections are detected and reported in an Open status word. A 1mA excitation source is used for resistance measurement in the lowest range setting (Pt100). For the Pt500, Pt1000 and Pt2000 ranges, the excitation current sources are 500µA, 250µA, and 100µA respectively.

Lead resistance correction is available in 2-wire mode, allowing for user compensation of cabling resistance in the measurement system. Resistance values may be entered for individual channels, which are subtracted from the measurement. The temperature measurements will reflect the compensated resistance values for the RTD for direct readout of the corrected temperature readings.

As with the Thermocouple mode, the temperature offset provisions allow for the same nulling of the temperature offsets in the system and operate similarly.

2-Wire is the simplest resistance measurement configuration, requiring only two wires per sensor. Measurements will be very sensitive to test cabling, as the excitation current and voltage measurements are through the same wires. Short or low resistance test leads are needed for accurate readings. Provisions for nulling the test lead resistances are provided via individual 2-wire offset resistance registers, allowing direct readings of the compensated measurements on a per channel basis.

3-Wire configuration relies on balanced test lead resistance on the Sense (+) and Sense (-) wires, so the voltage drop across each of the two current source lines are equal and cancel each other out. The differential voltage reading between the two sense lines along with the excitation current through the resistor is used in the resulting calculation of the sensor resistance. The test lead wire length will not affect the measurement provided the two lines are equal in resistance and is often the best compromise between wiring requirements and accuracy. In 3-Wire mode, the excitation current is split in half. Half of the total current flows on each of the sense lines (see 3-Wire RTD connection diagram).

4-Wire configuration provides optimal accuracy, allowing precise measurements without any constraints of short or balanced test leads, but requires 4 wires per sensor. The two sense wires measure the voltage at the sensor independently without undue influence of voltage drops due to the excitation current. This configuration is recommended where accuracy is a priority over the additional wiring requirements.

Low Voltage A/D Measurement Capability

The module can measure low voltage dynamic signals in the microvolt range with faster update rates to 4800 Hz. Readings can track dynamic signals when high rates are selected, with some increase in noise jitter. Optimal accuracy and reading stability will be achieved by low update rate selections.

Default configuration runs periodic maintenance in the background for self-test and calibration at 30 second intervals, which briefly suspends reading updates during the performance of these routines. For time critical measurements, the periodic internal processes may optionally be suspended for continuous and uninterrupted readings. During this time, these maintenance operations may be triggered manually by the user at suitable intervals.

Automatic Background Built-In Test (BIT)/Diagnostic Capability

Automatic background BIT testing is provided. Each channel is checked at periodic intervals for correct A/D operation using an internal measurement of an on-board resistor reference. The open input detection test applies a low-level current pulse to the A/D converter inputs and tests for a full-scale 3.3V limit, indicating an open sensor circuit. Any failure triggers an interrupt if enabled, with the results available in the status registers. The testing is transparent to the user and has no effect on the operation of this module. Enabled by default at power on, it may optionally be disabled.

Temperature Threshold Detect Programming

The TR1 provides the ability to program two temperature thresholds that will result in temperature alerts. For each threshold, a “low” and a “high” threshold value is specified that will be used to set the Temperature Alert statuses. The Temperature Threshold Low registers sets the threshold values to use to set the Temperature Alert Low status bit when the Temperature reading is below the low temperature threshold value. Conversely, the Temperature Threshold High registers sets the threshold values to use to set the Temperature Alert High status bit when the Temperature reading is above the high temperature threshold value. These threshold values are individually configurable on a per channel basis. A possible usage of the two temperature thresholds is to use the first threshold detection levels as an early warning pre-alarm level and the second threshold detection levels as an alarm limit value. For this purpose, the Detect 2 thresholds should be set at larger deviation values from the nominal temperature than the Detect 1 thresholds.

For example:

[Threshold Low 2] < [Threshold Low 1] < [Nominal Temperature] < [Threshold High 1] < [Threshold High 2]

This allows the Detect 1 thresholds to serve as a pre-alert warning of temperature excursion, while Detect 2 may represent an alarm condition.

|

Note

|

these detect thresholds are not necessarily set in this order and may be independently set either way. |

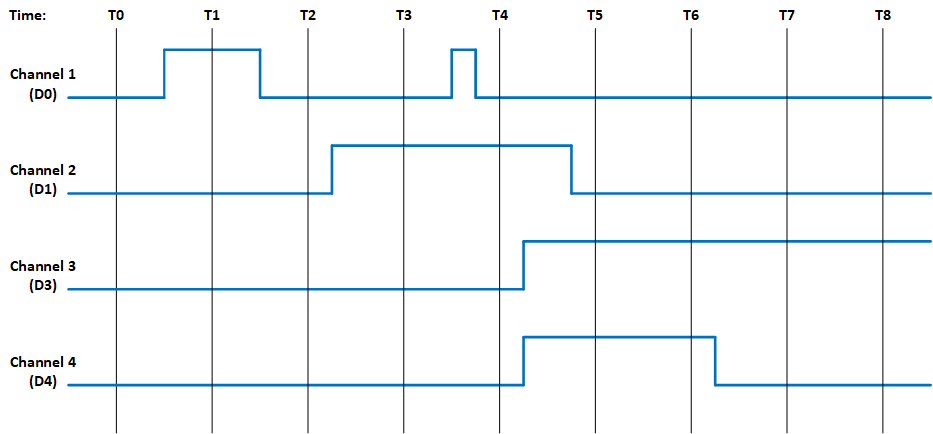

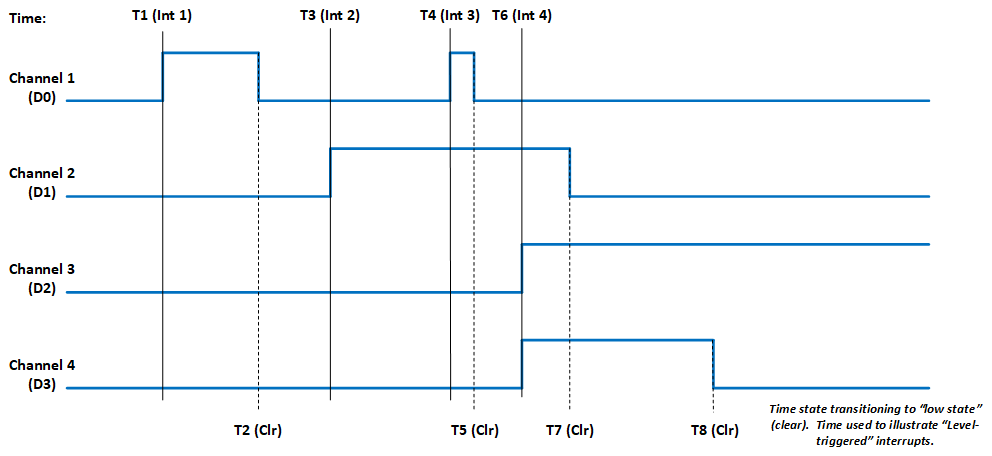

Status and Interrupts

The TR1 Function Module provide registers that indicate faults or events. Refer to “Status and Interrupts Module Manual” for the Principle of Operation description.

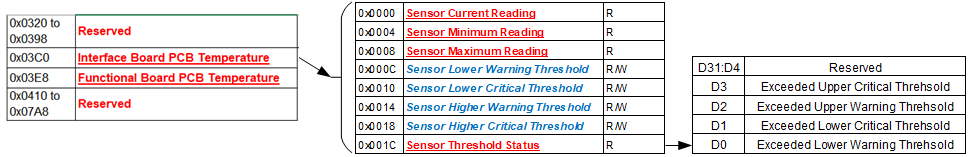

Module Common Registers

The TR1 Function Module includes module common registers that provide access to module-level bare metal/FPGA revisions & compile times, unique serial number information, and temperature/voltage/current monitoring. Refer to “Module Common Registers Module Manual” for the detailed information.

REGISTER DESCRIPTIONS

The register descriptions provide the Register Name, Type, Data Range, Read or Write information, power on default initialized values, a description of the function and a data table where applicable,

TR1 Measurement Registers

The TR1 measurement registers provide Temperature measurements (in both Celsius and Fahrenheit degrees), for RTD mode, Resistance measurements, and for Thermocouple mode, Voltage measurements.

Temperature (°C)

Function: |

Measures the temperature of the thermocouple/ RTD sensor. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R |

Initialized Value: |

N/A |

Operational Settings: |

RTD/Thermocouple temperature measurement in degrees Celsius. For Thermocouple, the measurement values will be dependent upon the appropriate selections made in the Thermocouple Type and Compensation Type registers. |

Temperature (°F)

Function: |

Measures the temperature of the thermocouple/ RTD sensor. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R |

Initialized Value: |

N/A |

Operational Settings: |

RTD/Thermocouple temperature measurement in degrees Fahrenheit. For Thermocouple, the value is dependent upon the appropriate and expected selections made in the Thermocouple Type and Compensation Type registers. |

Thermocouple - Specific Measurement Registers

When the TR1 module channel is configured for Thermocouple mode, in addition to the temperature measurements, the Voltage measurement is also available.

Voltage

Function: |

Measures the direct input voltages at the TR1 channels. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R |

Initialized Value: |

N/A |

Operational Settings: |

Voltage measurement of the TR1 channel in V. |

NOTE: the register does not include the cold junction compensation.

RTD - Specific Measurement Registers

When the TR1 module channel is configured for RTD mode, in addition to the temperature measurements, the Resistance measurement is also available.

Resistance

Function: |

Measures resistance of the RTD sensor. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R |

Initialized Value: |

N/A |

Operational Settings: |

Measures resistance in ohms. This measurement may optionally be adjusted through a user entry of a 2-wire lead resistance compensation value. |

TR1 Control Registers

The TR1 control registers provide the ability to configure the channels to either Thermocouple or RTD mode and specifying the sample rate. For Thermocouple channels, the configuration requirements include specification of the Thermocouple type and Thermocouple temperature compensation settings. For RTD channels, configuration requirements include specifying the RTD type, the RTD wire-measurement mode and resistance compensation (resistance compensation is only required for channels configured in 2-Wire mode).

Mode Select

Function: |

Configures the TR1 channel to either Thermocouple or RTD mode. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R/W |

Initialized Value: |

0xFF, bitmapped per channel (All channels in RTD Mode) |

Operational Settings: |

Configures the channel for Thermocouple (0) or RTD (1) mode. |

NOTE: for if Automatic Cold Junction Compensation Enable register is enabled, Channel 8 will automatically be configured in RTD mode.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Ch8 - configured automatically to RTD mode, if Automatic Cold Junction Compensation Enable = 1

Sample Rate

Function: |

Sets the sampling rate of the sensor. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x00 to 0x27 (See table) |

Read/Write: |

R/W |

Initialized Value: |

0x27 (3 Hz) |

Operational Settings: |

Set the value based on Sample Rate table. Note: lower rates provide greater stability and accuracy in the readings. Per channel configuration. |

Sample Rate Register Value |

Update Frequency (Hz) |

0x0 |

4800 |

0x1 |

2400 |

0x2 |

1600 |

0x3 |

1200 |

0x4 |

960 |

0x5 |

800 |

0x6 |

600 |

0x7 |

480 |

0x8 |

400 |

0x9 |

320 |

0xA |

300 |

0xB |

240 |

0xC |

200 |

0xD |

192 |

0xE |

160 |

0xF |

150 |

0x10 |

120 |

0x11 |

100 |

0x12 |

96 |

0x13 |

80 |

0x14 |

75 |

0x15 |

64 |

0x16 |

60 |

0x17 |

50 |

0x18 |

48 |

0x19 |

40 |

0x1A |

32 |

0x1B |

30 |

0x1C |

25 |

0x1D |

24 |

0x1E |

20 |

0x1F |

16 |

0x20 |

15 |

0x21 |

12 |

0x23 |

8 |

0x24 |

6 |

0x25 |

5 |

0x26 |

4 |

0x27 |

3 |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

D |

D |

D |

Offset Temperature

Function: |

Set a user defined offset temperature in °C. The value in this register is subtracted from the temperature readings. The raw voltage and resistance readings are not affected. Programming the Offset Temperature register provides the ability to null any system measurement errors and adjust slight variations in the thermocouple and measurement circuitry. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

0.0 |

Operational Settings: |

Sets the user defined offset temperature to be used. |

Thermocouple - Specific Control

For TR1 module channels configured in Thermocouple mode, additional configurations and controls include the Thermocouple Type, Automatic Cold Junction Compensation Enable, the Compensation Type, and the Compensation Temperature.

For time critical measurements, such as using a channel for low voltage A/D measurements, the TR1 module provides registers to suspend the maintenance operations which briefly suspends the updates of measurement readings.

Thermocouple Type

Function: |

Sets the type of thermocouple (J, K, T, E, N, B, R, S) |

Type: |

ASCII Hex as unsigned binary word (32-bit) |

Data Range: |

See table. |

Read/Write: |

R/W |

Initialized Value: |

'K' (0x4B) (Default set on channel configuration switch from RTD to Thermocouple mode) |

Operational Settings: |

Set the Thermocouple Type as specified in the table. |

NOTE: the register entry is the ASCII hex equivalent value for the thermocouple type.

Thermocouple Type |

ASCII Entry (Hex Conversion) |

J |

0x4A |

K |

0x4B |

T |

0x54 |

E |

0x45 |

N |

0x4E |

B |

0x42 |

R |

0x52 |

S |

0x53 |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

D |

D |

D |

D |

D |

Automatic Cold Junction Compensation Enable

Function: |

When Automatic Cold Junction Compensation is enabled, Channel 8 is automatically configured in RTD mode, to allow its temperature reading to be used for compensation of terminal connection temperatures at other than 0 deg C. NOTE: the RTD temperature reading for Channel 8 will be used as the Thermocouple Compensation Temperature only for channels with the Compensation Type set to “automatic compensation”; otherwise the manual temperature compensation entries for those channels will still apply. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0 or 1 |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

Enable (1) or disable (0) to use the RTD reading for Channel 8 as the Compensation Temperature when Compensation Type is set to “automatic compensation”. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

Compensation Type

Function: |

Selects the compensation value source to use for the Thermocouple Temperature value. The selection can either be the user specified value in the Compensation Temperature register or the Channel 8 RTD reading from the accessory Cold Junction Compensation Block. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0 (user specified temperature) or 1 (use Ch.8 temperature reading) |

Read/Write: |

R/W |

Initialized Value: |

0x0 (manual) |

Operational Settings: |

Set to user defined selection (0) to use the value in the Compensation Temperature register. Set to automatic compensation (1) to use Channel 8 RTD reading from the Cold Junction Compensation Block. |

|

Note

|

when the Compensation Type for any channel is set to automatic compensation (1), the Automatic Cold Junction Compensation Enable register should be enabled (1) as well to ensure channel 8 properly compensates the Thermocouple Temperature readings. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

Compensation Temperature

Function: |

Set a user defined compensation temperature in °C. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

0.0 (NOTE: Value is reset to default whenever channel configuration is toggled between Thermocouple and RTD mode.) |

Operational Settings: |

Sets the user defined compensation temperature to be used. |

Suspend Background Maintenance Operations Register

The default configuration of the module is to run periodic self-test and calibration at 30 second intervals. During these operations, updates to the measurement readings are briefly suspended. For time critical measurements, such as using a channel for low voltage A/D measurements, the periodic internal processes may optionally be suspended for continuous and uninterrupted readings. During this suspended time, the maintenance operations for calibration and open-line detect may be triggered manually by the application at suitable intervals.

Suspend Background Maintenance Operations

Function: |

Holds off the performance of periodic maintenance routines for internal system calibration (TC mode), open line status checking, and built in test (BIT). Used for dynamic measurements for continuous reading updates without interruption from the brief maintenance operations. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R/W |

Initialized Value: |

0 (All channels run maintenance operations on a scheduled basis) |

Operational Settings: |

Suspends periodic operations for open line status check, system calibration, and BIT. Set to 0 to perform periodic operations for channel (default). Set bit to 1 to suspend the background maintenance operations for the specified channel. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Run System Calibration

Function: |

Triggers performance of internal system calibration for channels where the periodic maintenance operations have been disabled. The calibration is normally run at 2 minute intervals to compensate for any internal drift on measurements. This one-time trigger is only used when the periodic schedule has been disabled for time critical measurements. This allows the user to run the routine in between measurement sessions. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

Write a 1 to the corresponding bit for the channel. Bit is self-clearing and will reset to zero on completion of the routine. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Run Open-Line Check

Function: |

Triggers check for open or unconnected channels to update the open status indication. This is only used when the periodic schedule has been disabled for time critical measurements. This allows the application to run the routine in between measurement sessions. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

Write a 1 to the corresponding bit for the channel. Bit is self-clearing and will reset to zero on completion of the routine. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Run BIT

Function: |

Triggers Built-In-Test to detect out of tolerance conditions on the measurement circuitry. Only used when the periodic schedule for the channel has been disabled for time critical measurements. This allows the user to run the routine in between measurement sessions. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

Write a 1 to the corresponding bit for the channel. Bit is self-clearing and will reset to zero on completion of the routine. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

RTD - Specific Control

For TR1 module channels configured in RTD mode, additional configurations and controls include the RTD Type, Wire Measurement Mode and 2-Wire Lead Resistance Compensation

RTD Type

Function: |

RTD nominal resistance at 0°C. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

See table |

Read/Write: |

R/W |

Initialized Value: |

100.0 (0x42C8 0000 in floating point) |

Operational Settings: |

Set the RTD Type as specified in the table. |

RTD Type |

Description |

Pt100 |

0-100 Ω RTD; resistance range of 0 Ω to approximately 500 Ω |

Pt500 |

0-500 Ω RTD; resistance range of 0 Ω to approximately 2000 Ω |

Pt1000 |

0-1000 Ω.RTD; resistance range of 0 Ω to approximately 4000 Ω |

Pt2000 |

0-2000 Ω.RTD; resistance range of 0 Ω to approximately 8000 Ω |

Wire Measurement Mode

Function: |

Sets the RTD sensor configuration: 2, 3 or 4 wire. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

2 - 4 |

Read/Write: |

R/W |

Initialized Value: |

2 (Value is set to 2-wire default whenever channel configuration mode is changed to RTD. |

Operational Settings: |

Set the Wire Measurement Mode as specified in the table. |

Wire Measurement Mode Value |

Description |

2 |

2-wire configuration |

3 |

3-wire configuration |

4 |

4-wire configuration |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

2-Wire Lead Resistance Compensation

Function: |

Set a user defined compensation resistance in ohms, primarily required for channels that are configured for 2-wire configuration in the Wire Measurement Mode register. This allows test lead or cabling resistances to be cancelled out when using a 2-wire configuration. The Resistance measurement reading is adjusted by subtracting the value set in this register to null test lead and cabling resistance. This resistance offset is also applied in 3- and 4-wire modes, though typically not required in those modes. NOTE: the applied offsets will also affect the corresponding temperature readings as the adjusted resistance values are used for the internal calculation of temperature for the RTD sensors. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

0.0 |

Operational Settings: |

Set the TOTAL lead resistance to be subtracted from the resistance measurement and reported in the Resistance register. |

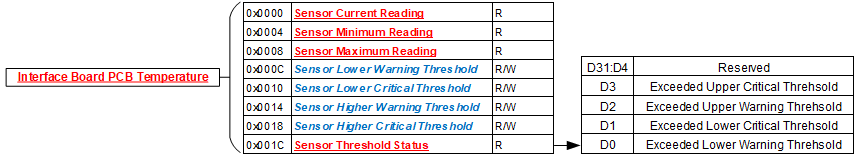

Temperature Threshold Detect Programming

The TR1 Temperature Threshold registers provide the ability program two temperature thresholds that will result in temperature alerts.

Temperature Threshold Detect 1

A “low” and a “high” threshold value is specified for each temperature threshold that will be used to set the Temperature Alert statuses. The Temperature Threshold Low 1 register sets the threshold value to use to set the Temperature Alert Low 1 status bit when the Temperature reading is below the low temperature threshold value. Conversely, the Temperature Threshold High 1 register sets the threshold values to use to set the Temperature Alert High 1 status bit when the Temperature reading is above the high temperature threshold value. These threshold values are individually configurable on a per channel basis.

Temperature Threshold Low 1

Function: |

Sets Temperature Threshold Low 1 value in degrees Celsius for each channel. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

-40° C |

Operational Settings: |

If the temperature drops below this set value, then a Temperature Alert Low 1 Status will be set. An interrupt will occur if the Temperature Alert Low 1 Interrupt Enable register is set to 1. |

Temperature Threshold High 1

Function: |

Sets Temperature Threshold High 1 value in degrees Celsius for each channel. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

25° C |

Operational Settings: |

If the temperature exceeds the set value, then a Temperature Alert High 1 Status will be set. An interrupt will occur if the Temperature Alert High 1 Interrupt Enable register is set to 1. |

Temperature Threshold Detect 2

A “low” and a “high” threshold value is specified for each temperature threshold that will be used to set the Temperature Alert statuses. The Temperature Threshold Low 2 register sets the threshold value to use to set the Temperature Alert Low 2 status bit when the Temperature reading is below the low temperature threshold value. Conversely, the Temperature Threshold High 2 register sets the threshold values to use to set the Temperature Alert High 2 status bit when the Temperature reading is above the high temperature threshold value. These threshold values are individually configurable on a per channel basis.

Temperature Threshold Low 2

Function: |

Sets Temperature Threshold Low 2 value in degrees Celsius for each channel. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

0°C |

Operational Settings: |

If the temperature drops below the set value, then a Temperature Alert Low 2 Status will be set. An interrupt will occur if the Temperature Alert Low 2 Interrupt Enable register is set to 1. |

Temperature Threshold High 2

Function: |

Sets Alert Temperature High 2 value in degrees Celsius for each channel. |

Type: |

Single Precision Floating Point Value (IEEE-754) |

Data Range: |

N/A |

Read/Write: |

R/W |

Initialized Value: |

100° C |

Operational Settings: |

If the temperature exceeds the set value, then a Temperature Alert High 2 Status will be set. An interrupt will occur if the Temperature Alert High 2 Interrupt Enable register is set to 1. |

Module Common Registers

Refer to “Module Common Registers Module Manual” for the register descriptions.

Status and Interrupt Registers

The TR1 Module provides status registers for BIT, Open, and Temperature Alert.

Channel Status Enabled

Function: |

Determines whether to update the status for the channels. This feature can be used to “mask” status bits of unused channels in status registers that are bitmapped by channel. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF (Channel Status) |

Read/Write: |

R/W |

Initialized Value: |

0x0000 00FF |

Operational Settings: |

When the bit corresponding to a given channel in the Channel Status Enabled register is not enabled (0) the status will be masked and report “0” or “no failure”. This applies to all statuses that are bitmapped by channel (BIT Status, Open Status, Temperature Alerts and Summary Status). |

|

Note

|

Background BIT will continue to run even if the Channel Status Enabled is set to 0. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

BIT Status

There are four registers associated with the BIT Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Indicates the corresponding channels associated with the channel’s BIT status or configuration |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

BIT Dynamic Status |

|||||||||||||||

BIT Latched Status |

|||||||||||||||

BIT Interrupt Enable |

|||||||||||||||

BIT Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Open Status

There are four registers associated with the Open Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s Open status indication for an unconnected input. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Open Dynamic Status |

|||||||||||||||

Open Latched Status |

|||||||||||||||

Open Interrupt Enable |

|||||||||||||||

Open Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Temperature Alert Status

There are four registers associated with each of the Temperature Alert Statuses: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s Temperature Alert indication for temperature readings that are below or above the associated thresholds. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Temperature Alert Low 1 Dynamic Status |

|||||||||||||||

Temperature Alert Low 1 Latched Status |

|||||||||||||||

Temperature Alert Low 1 Interrupt Enable |

|||||||||||||||

Temperature Alert Low 1 Set Edge/Level Interrupt |

|||||||||||||||

Temperature Alert High 1 Dynamic Status |

|||||||||||||||

Temperature Alert High 1 Latched Status |

|||||||||||||||

Temperature Alert High 1 Interrupt Enable |

|||||||||||||||

Temperature Alert High 1 Set Edge/Level Interrupt |

|||||||||||||||

Temperature Alert Low 2 Dynamic Status |

|||||||||||||||

Temperature Alert Low 2 Latched Status |

|||||||||||||||

Temperature Alert Low 2 Interrupt Enable |

|||||||||||||||

Temperature Alert Low 2 Set Edge/Level Interrupt |

|||||||||||||||

Temperature Alert High 2 Dynamic Status |

|||||||||||||||

Temperature Alert High 2 Latched Status |

|||||||||||||||

Temperature Alert High 2 Interrupt Enable |

|||||||||||||||

Temperature Alert High 1 Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Summary Status

There are four registers associated with the Summary Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit when a fault is detected for BIT or Open on that channel. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 00FF |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Summary Status Dynamic Status |

|||||||||||||||

Summary Status Latched Status |

|||||||||||||||

Summary Status Interrupt Enable |

|||||||||||||||

Summary Status Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Interrupt Vector and Steering

When interrupts are enabled, the interrupt vector associated with the specific interrupt can be programmed (typically with a unique number/identifier) such that it can be utilized in the Interrupt Service Routine (ISR) to identify the type of interrupt. When an interrupt occurs, the contents of the Interrupt Vector registers is reported as part of the interrupt mechanism.

In addition to specifying the interrupt vector, the interrupt can be directed (“steered”) to the native bus or to the application running on the onboard ARM processor.

|

Note

|

The Interrupt Vector and Interrupt Steering registers are mapped to the Motherboard Common Memory and these registers are associated with the Module Slot position (refer to Function Register Map). |

Interrupt Vector

Function: |

Set an identifier for the interrupt. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

When an interrupt occurs, this value is reported as part of the interrupt mechanism. |

Interrupt Steering

Function: |

Sets where to direct the interrupt. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

See table |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

When an interrupt occurs, the interrupt is sent as specified: |

Direct Interrupt to VME |

1 |

Direct Interrupt to ARM Processor (via SerDes) (Custom App on ARM or NAI Ethernet Listener App) |

2 |

Direct Interrupt to PCIe Bus |

5 |

Direct Interrupt to cPCI Bus |

6 |

FUNCTION REGISTER MAP

Key:

Bold Italic |

= Configuration/Control |

Bold Underline |

= Measurement/Status |

*When an event is detected, the bit associated with the event is set in this register and will remain set until the user clears the event bit. Clearing the bit requires writing a 1 back to the specific bit that was set when read (i.e. write-1-to-clear, writing a '1' to a bit set to '1' will set the bit to '0').

~ Data is always in Floating Point.

TR1 Measurement Registers

Addr (Hex) |

Name |

Read/Write |

0x1004 |

Temperature (ºC) Ch 1~ |

R |

0x1044 |

Temperature (ºC) Ch 2~ |

R |

0x1084 |

Temperature (ºC) Ch 3~ |

R |

0x10C4 |

Temperature (ºC) Ch 4~ |

R |

0x1104 |

Temperature (ºC) Ch 5~ |

R |

0x1144 |

Temperature (ºC) Ch 6~ |

R |

0x1184 |

Temperature (ºC) Ch 7~ |

R |

0x11C4 |

Temperature (ºC) Ch 8~ |

R |

Addr (Hex) |

Name |

Read/Write |

0x1008 |

Temperature (ºF) Ch 1~ |

R |

0x1048 |

Temperature (ºF) Ch 2~ |

R |

0x1088 |

Temperature (ºF) Ch 3~ |

R |

0x10C8 |

Temperature (ºF) Ch 4~ |

R |

0x1108 |

Temperature (ºF) Ch 5~ |

R |

0x1148 |

Temperature (ºF) Ch 6~ |

R |

0x1188 |

Temperature (ºF) Ch 7~ |

R |

0x11C8 |

Temperature (ºF) Ch 8~ |

R |

Thermocouple-Specific Measurement Registers

Addr (Hex) |

Name |

Read/Write |

0x1000 |

Voltage Ch 1~ |

R |

0x1040 |

Voltage Ch 2~ |

R |

0x1080 |

Voltage Ch 3~ |

R |

0x10C0 |

Voltage Ch 4~ |

R |

0x1100 |

Voltage Ch 5~ |

R |

0x1140 |

Voltage Ch 6~ |

R |

0x1180 |

Voltage Ch 7~ |

R |

0x11C0 |

Voltage Ch 8~ |

R |

RTD-Specific Measurement Registers

Addr (Hex) |

Name |

Read/Write |

0x1000 |

Resistance Ch 1~ |

R |

0x1040 |

Resistance Ch 2~ |

R |

0x1080 |

Resistance Ch 3~ |

R |

0x10C0 |

Resistance Ch 4~ |

R |

0x1100 |

Resistance Ch 5~ |

R |

0x1140 |

Resistance Ch 6~ |

R |

0x1180 |

Resistance Ch 7~ |

R |

0x11C0 |

Resistance Ch 8~ |

R |

TR1 Control Registers

Addr (Hex) |

Name |

Read/Write |

0x2000 |

Mode Select Ch 1-8 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1028 |

Sample Rate Ch 1 |

R/W |

0x1068 |

Sample Rate Ch 2 |

R/W |

0x10A8 |

Sample Rate Ch 3 |

R/W |

0x10E8 |

Sample Rate Ch 4 |

R/W |

0x1128 |

Sample Rate Ch 5 |

R/W |

0x1168 |

Sample Rate Ch 6 |

R/W |

0x11A8 |

Sample Rate Ch 7 |

R/W |

0x11E8 |

Sample Rate Ch 8 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x102C |

Offset Temperature Ch 1~ |

R/W |

0x106C |

Offset Temperature Ch 2~ |

R/W |

0x10AC |

Offset Temperature Ch 3~ |

R/W |

0x10EC |

Offset Temperature Ch 4~ |

R/W |

0x112C |

Offset Temperature Ch 5~ |

R/W |

0x116C |

Offset Temperature Ch 6~ |

R/W |

0x11AC |

Offset Temperature Ch 7~ |

R/W |

0x11EC |

Offset Temperature Ch 8~ |

R/W |

Thermocouple-Specific Control Registers

Addr (Hex) |

Name |

Read/Write |

0x100C |

Thermocouple Type Ch 1 |

R/W |

0x104C |

Thermocouple Type Ch 2 |

R/W |

0x108C |

Thermocouple Type Ch 3 |

R/W |

0x10CC |

Thermocouple Type Ch 4 |

R/W |

0x110C |

Thermocouple Type Ch 5 |

R/W |

0x114C |

Thermocouple Type Ch 6 |

R/W |

0x118C |

Thermocouple Type Ch 7 |

R/W |

0x11CC |

Thermocouple Type Ch 8 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x2004 |

Automatic Cold Junction Compensation Enable |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1010 |

Compensation Type Ch 1 |

R/W |

0x1050 |

Compensation Type Ch 2 |

R/W |

0x1090 |

Compensation Type Ch 3 |

R/W |

0x10D0 |

Compensation Type Ch 4 |

R/W |

0x1110 |

Compensation Type Ch 5 |

R/W |

0x1150 |

Compensation Type Ch 6 |

R/W |

0x1190 |

Compensation Type Ch 7 |

R/W |

0x11D0 |

Compensation Type Ch 8 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1014 |

Compensation Temperature Ch 1~ |

R/W |

0x1054 |

Compensation Temperature Ch 2~ |

R/W |

0x1094 |

Compensation Temperature Ch 3~ |

R/W |

0x10D4 |

Compensation Temperature Ch 4~ |

R/W |

0x1114 |

Compensation Temperature Ch 5~ |

R/W |

0x1154 |

Compensation Temperature Ch 6~ |

R/W |

0x1194 |

Compensation Temperature Ch 7~ |

R/W |

0x11D4 |

Compensation Temperature Ch 8~ |

R/W |

Thermocouple-Specific Suspend Maintenance Operations Registers

Addr (Hex) |

Name |

Read/Write |

0x2008 |

Suspend Background Operations |

R/W |

0x200C |

Run System Calibration |

R/W |

0x2010 |

Run Open-Line Check |

R/W |

0x2014 |

Run BIT |

R/W |

RTD-Specific Control Registers

Addr (Hex) |

Name |

Read/Write |

0x100C |

RTD Type Ch 1 |

R/W |

0x104C |

RTD Type Ch 2 |

R/W |

0x108C |

RTD Type Ch 3 |

R/W |

0x10CC |

RTD Type Ch 4 |

R/W |

0x110C |

RTD Type Ch 5 |

R/W |

0x114C |

RTD Type Ch 6 |

R/W |

0x118C |

RTD Type Ch 7 |

R/W |

0x11CC |

RTD Type Ch 8 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1010 |

Wire Measurement Mode Ch 1 |

R/W |

0x1050 |

Wire Measurement Mode Ch 2 |

R/W |

0x1090 |

Wire Measurement Mode Ch 3 |

R/W |

0x10D0 |

Wire Measurement Mode Ch 4 |

R/W |

0x1110 |

Wire Measurement Mode Ch 5 |

R/W |

0x1150 |

Wire Measurement Mode Ch 6 |

R/W |

0x1190 |

Wire Measurement Mode Ch 7 |

R/W |

0x11D0 |

Wire Measurement Mode Ch 8 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1014 |

2-Wire Lead Resistance Compensation Ch 1~ |

R/W |

0x1054 |

2-Wire Lead Resistance Compensation Ch 2~ |

R/W |

0x1094 |

2-Wire Lead Resistance Compensation Ch 3~ |

R/W |

0x10D4 |

2-Wire Lead Resistance Compensation Ch 4~ |

R/W |

0x1114 |

2-Wire Lead Resistance Compensation Ch 5~ |

R/W |

0x1154 |

2-Wire Lead Resistance Compensation Ch 6~ |

R/W |

0x1194 |

2-Wire Lead Resistance Compensation Ch 7~ |

R/W |

0x11D4 |

2-Wire Lead Resistance Compensation Ch 8~ |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x2008 |

Suspend Background Operations |

R/W |

0x2010 |

Run Open-Line Check |

R/W |

0x2014 |

Run BIT |

R/W |

Temperature Threshold Detect Programming Registers

Addr (Hex) |

Name |

Read/Write |

0x1018 |

Air Temperature Low 1 Ch 1~ |

R/W |

0x1058 |

Air Temperature Low 1 Ch 2~ |

R/W |

0x1098 |

Air Temperature Low 1 Ch 3~ |

R/W |

0x10D8 |

Air Temperature Low 1 Ch 4~ |

R/W |

0x1118 |

Air Temperature Low 1 Ch 5~ |

R/W |

0x1158 |

Air Temperature Low 1 Ch 6~ |

R/W |

0x1198 |

Air Temperature Low 1 Ch 7~ |

R/W |

0x11D8 |

Air Temperature Low 1 Ch 8~ |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x101C |

Air Temperature Low 2 Ch 1~ |

R/W |

0x105C |

Air Temperature Low 2 Ch 2~ |

R/W |

0x109C |

Air Temperature Low 2 Ch 3~ |

R/W |

0x10DC |

Air Temperature Low 2 Ch 4~ |

R/W |

0x111C |

Air Temperature Low 2 Ch 5~ |

R/W |

0x115C |

Air Temperature Low 2 Ch 6~ |

R/W |

0x119C |

Air Temperature Low 2 Ch 7~ |

R/W |

0x11DC |

Air Temperature Low 2 Ch 8~ |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1020 |

Air Temperature High 1 Ch 1~ |

R/W |

0x1060 |

Air Temperature High 1 Ch 2~ |

R/W |

0x10A0 |

Air Temperature High 1 Ch 3~ |

R/W |

0x10E0 |

Air Temperature High 1 Ch 4~ |

R/W |

0x1120 |

Air Temperature High 1 Ch 5~ |

R/W |

0x1160 |

Air Temperature High 1 Ch 6~ |

R/W |

0x11A0 |

Air Temperature High 1 Ch 7~ |

R/W |

0x11E0 |

Air Temperature High 1 Ch 8~ |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1024 |

Air Temperature High 2 Ch 1~ |

R/W |

0x1064 |

Air Temperature High 2 Ch 2~ |

R/W |

0x10A4 |

Air Temperature High 2 Ch 3~ |

R/W |

0x10E4 |

Air Temperature High 2 Ch 4~ |

R/W |

0x1124 |

Air Temperature High 2 Ch 5~ |

R/W |

0x1164 |

Air Temperature High 2 Ch 6~ |

R/W |

0x11A4 |

Air Temperature High 2 Ch 7~ |

R/W |

0x11E4 |

Air Temperature High 2 Ch 8~ |

R/W |

Module Common Registers

Refer to “Module Common Registers Module Manual” for the Module Common Registers Function Register Map.

Status Registers

Addr (Hex) |

Name |

Read/Write |

0x02B0 |

Channel Status Enabled |

R/W |

BIT Status

Addr (Hex) |

Name |

Read/Write |

0x0800 |

Dynamic Status |

R |

0x0804 |

Latched Status* |

R/W |

0x0808 |

Interrupt Enable |

R/W |

0x080C |

Set Edge/Level Interrupt |

R/W |

Open

Addr (Hex) |

Name |

Read/Write |

0x0810 |

Dynamic Status |

R |

0x0814 |

Latched Status* |

R/W |

0x0818 |

Interrupt Enable |

R/W |

0x081C |

Set Edge/Level Interrupt |

R/W |

Temperature Alert Low 1

Addr (Hex) |

Name |

Read/Write |

0x0820 |

Dynamic Status |

R |

0x0824 |

Latched Status* |

R/W |

0x0828 |

Interrupt Enable |

R/W |

0x082C |

Set Edge/Level Interrupt |

R/W |

Temperature Alert Low 2

Addr (Hex) |

Name |

Read/Write |

0x0830 |

Dynamic Status |

R |

0x0834 |

Latched Status* |

R/W |

0x0838 |

Interrupt Enable |

R/W |

0x083C |

Set Edge/Level Interrupt |

R/W |

Temperature Alert High 1

Addr (Hex) |

Name |

Read/Write |

0x0840 |

Dynamic Status |

R |

0x0844 |

Latched Status* |

R/W |

0x0848 |

Interrupt Enable |

R/W |

0x084C |

Set Edge/Level Interrupt |

R/W |

Temperature Alert High 2

Addr (Hex) |

Name |

Read/Write |

0x0850 |

Dynamic Status |

R |

0x0854 |

Latched Status* |

R/W |

0x0858 |

Interrupt Enable |

R/W |

0x085C |

Set Edge/Level Interrupt |

R/W |

Summary Status

Addr (Hex) |

Name |

Read/Write |

0x09A0 |

Dynamic Status |

R |

0x09A4 |

Latched Status* |

R/W |

0x09A8 |

Interrupt Enable |

R/W |

0x09AC |

Set Edge/Level Interrupt |

R/W |

Interrupt Registers

The Interrupt Vector and Interrupt Steering registers are located on the Motherboard Memory Space and do not require any Module Address Offsets. These registers are accessed using the absolute addresses listed in the table below.

Addr (Hex) |

Name |

Read/Write |

0x0500 |

Module 1 Interrupt Vector 1 - BIT |

R/W |

0x0504 |

Module 1 Interrupt Vector 2 - Open |

R/W |

0x0508 |

Module 1 Interrupt Vector 3 - Temperature Alert Low 1 |

R/W |

0x050C |

Module 1 Interrupt Vector 4 - Temperature Alert Low 2 |

R/W |

0x0510 |

Module 1 Interrupt Vector 5 - Temperature Alert High 1 |

R/W |

0x0514 |

Module 1 Interrupt Vector 6 - Temperature Alert High 2 |

R/W |

0x0518 to 0x0564 |

Module 1 Interrupt Vector 7-26 - Reserved |

R/W |

0x0568 |

Module 1 Interrupt Vector 27 - Summary |

R/W |

0x056C to 0x057C |

Module 1 Interrupt Vector 28-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0600 |

Module 1 Interrupt Steering 1 - BIT |

R/W |

0x0604 |

Module 1 Interrupt Steering 2 - Open |

R/W |

0x0608 |

Module 1 Interrupt Steering 3 - Temperature Alert Low 1 |

R/W |

0x060C |

Module 1 Interrupt Steering 4 - Temperature Alert Low 2 |

R/W |

0x0610 |

Module 1 Interrupt Steering 5 - Temperature Alert High 1 |

R/W |

0x0614 |

Module 1 Interrupt Steering 6 - Temperature Alert High 2 |

R/W |

0x0618 to 0x0664 |

Module 1 Interrupt Steering 7-26 - Reserved |

R/W |

0x0668 |

Module 1 Interrupt Steering 27 - Summary |

R/W |

0x066C to 0x067C |

Module 1 Interrupt Steering 28-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0700 |

Module 2 Interrupt Vector 1 - BIT |

R/W |

0x0704 |

Module 2 Interrupt Vector 2 - Open |

R/W |

0x0708 |

Module 2 Interrupt Vector 3 - Temperature Alert Low 1 |

R/W |

0x070C |

Module 2 Interrupt Vector 4 - Temperature Alert Low 2 |

R/W |

0x0710 |

Module 2 Interrupt Vector 5 - Temperature Alert High 1 |

R/W |

0x0714 |

Module 2 Interrupt Vector 6 - Temperature Alert High 2 |

R/W |

0x0718 to 0x0764 |

Module 2 Interrupt Vector 7-26 - Reserved |

R/W |

0x0768 |

Module 2 Interrupt Vector 27 - Summary |

R/W |

0x076C to 0x077C |

Module 2 Interrupt Vector 28-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0800 |

Module 2 Interrupt Steering 1 - BIT |

R/W |

0x0804 |

Module 2 Interrupt Steering 2 - Open |

R/W |

0x0808 |

Module 2 Interrupt Steering 3 - Temperature Alert Low 1 |

R/W |

0x080C |

Module 2 Interrupt Steering 4 - Temperature Alert Low 2 |

R/W |

0x0810 |

Module 2 Interrupt Steering 5 - Temperature Alert High 1 |

R/W |

0x0814 |

Module 2 Interrupt Steering 6 - Temperature Alert High 2 |

R/W |

0x0818 to 0x0864 |

Module 2 Interrupt Steering 7-26 - Reserved |

R/W |

0x0868 |

Module 2 Interrupt Steering 27 - Summary |

R/W |

0x086C to 0x087C |

Module 2 Interrupt Steering 28-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0900 |

Module 3 Interrupt Vector 1 - BIT |

R/W |

0x0904 |

Module 3 Interrupt Vector 2 - Open |

R/W |

0x0908 |

Module 3 Interrupt Vector 3 - Temperature Alert Low 1 |

R/W |

0x090C |

Module 3 Interrupt Vector 4 - Temperature Alert Low 2 |

R/W |

0x0910 |

Module 3 Interrupt Vector 5 - Temperature Alert High 1 |

R/W |

0x0914 |

Module 3 Interrupt Vector 6 - Temperature Alert High 2 |

R/W |

0x0918 to 0x0964 |

Module 3 Interrupt Vector 7-26 - Reserved |

R/W |

0x0968 |

Module 3 Interrupt Vector 27 - Summary |

R/W |

0x096C to 0x097C |

Module 3 Interrupt Vector 28-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0A00 |

Module 3 Interrupt Steering 1 - BIT |

R/W |

0x0A04 |

Module 3 Interrupt Steering 2 - Open |

R/W |

0x0A08 |

Module 3 Interrupt Steering 3 - Temperature Alert Low 1 |

R/W |

0x0A0C |

Module 3 Interrupt Steering 4 - Temperature Alert Low 2 |

R/W |

0x0A10 |

Module 3 Interrupt Steering 5 - Temperature Alert High 1 |

R/W |

0x0A14 |

Module 3 Interrupt Steering 6 - Temperature Alert High 2 |

R/W |

0x0A18 to 0x0A64 |

Module 3 Interrupt Steering 7-26 - Reserved |

R/W |

0x0A68 |

Module 3 Interrupt Steering 27 - Summary |

R/W |

0x0A6C to 0x0A7C |

Module 3 Interrupt Steering 28-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0B00 |

Module 4 Interrupt Vector 1 - BIT |

R/W |

0x0B04 |

Module 4 Interrupt Vector 2 - Open |

R/W |

0x0B08 |

Module 4 Interrupt Vector 3 - Temperature Alert Low 1 |

R/W |

0x0B0C |

Module 4 Interrupt Vector 4 - Temperature Alert Low 2 |

R/W |

0x0B10 |

Module 4 Interrupt Vector 5 - Temperature Alert High 1 |

R/W |

0x0B14 |