DS1-DSN Manual

Edit this on GitLab

INTRODUCTION

Modules DS and DR are Synchro/Resolver Simulation Modules. Synchros and Resolvers are transformer-type voltage/current transducers that convert a shaft or other rotating device’s angular position and/or velocity to a multi-wire AC electrical signal. Both deliver signals proportional to the Sine and/or Cosine of the shaft angle. A Digital-to-Synchro or Digital-to-Resolver simulator is used to generate digital representations of angle/ commands to corresponding Synchro/Resolver AC signals.

A wide variety of DS and DR modules are available to cover the range of excitation voltages/frequency, include extensive field-parameter programmability, and provide a full operating envelope choice for simulating virtually any type Synchro or Resolver. By eliminating the need for external transformers and operating with lower AC reference frequencies, these solid-state designs offer huge space savings.

See Model Designations table below for a description of the available DS and DR configurations.

Module ID |

No. of Channels |

Full Scale Output Voltage (RMS VL-L) |

Output Load |

Frequency Range (Hz) |

|

Synchro |

Resolver |

||||

DS1 |

DR1 |

1* |

2-28 |

3 VA @ 28 VRMS |

47-1k |

DS2 |

DR2 |

1* |

2-28 |

3 VA @ 28 VRMS |

1k-5k |

DS3 |

DR3 |

1* |

2-28 |

3 VA @ 28 VRMS |

5k-10k |

DS4 |

DR4 |

1* |

2-28 |

3 VA @ 28 VRMS |

10k-20k |

DS5 |

DR5 |

1* |

28-90 |

3 VA @ 90 VRMS |

47-1k |

DS8 |

1 |

90 |

8 VA @ 90 VRMS |

400 |

|

DSA |

DRA |

2 |

2-28 |

1.5 VA @ 28 VRMS |

47-1k |

DSB |

DRB |

2 |

2-28 |

1.5 VA @ 28 VRMS |

1k-5k |

DSC |

DRC |

2 |

2-28 |

1.5 VA @ 28 VRMS |

5k-10k |

DSD |

DRD |

2 |

2-28 |

1.5 VA @ 28 VRMS |

10k-20k |

DSE |

DRE |

2 |

28-90 |

2.2 VA @ 90 VRMS |

47-1k |

DSJ |

DRJ |

3 |

2-28 |

0.5 VA @ 28 VRMS |

47-1k |

DSK |

DRK |

3 |

2-28 |

0.5 VA @ 28 VRMS |

1k-5k |

DSL |

DRL |

3 |

2-28 |

0.5 VA @ 28 VRMS |

5k-10k |

DSM |

DRM |

3 |

2-28 |

0.5 VA @ 28 VRMS |

10k-20k |

DSN |

DRN |

3 |

28-90 |

0.5 VA @ 90 VRMS |

47-1k |

There are three types of D/S and D/R modules:

-

3-Channel Modules: These high-density modules have a lower power output drive (0.5 VA per channel, maximum). The lower power output drive is ideal for driving solid-state input instruments, gauges, and Synchro Booster Amplifiers (SBAs).

-

2-Channel Modules: The 2-channel modules have a standard power output of 2.2 VA (28-90 VLL or 1.5 VA (2-28 VLL) per channel, maximum.

-

Single-Channel Modules: The single-channel modules have a high-power output drive capability (3 VA per channel, maximum).

* Contact factory for single channel availability

PRINCIPLE OF OPERATION

The Digital-to-Synchro/Resolver module includes optional format selections (synchro or resolver). A background calibration feature (pending), that is totally transparent to the operation of the channels, maintains outputs for all load and environmental conditions. Each channel can be programmed for a different line-to-line voltage, which can be programmed for either ratio or fixed output mode. When set to ratio mode, each channel utilizes a transformation ratio (TR) which sets the maximum output signal voltage in relation to the input reference voltage (TR = Max Output Voltage/Reference Voltage). This ratiometric design eliminates errors caused by variations in reference voltage by allowing the output voltage to adjust with it. When set to fixed mode, the output voltage is absolute and does not change with reference voltage variations. Module power ON/OFF capability provided for shutting down channels.

Built-In Test (BIT)/Diagnostic Capability

The board supports three types of built-in tests: Power-On, Continuous Background and Initiated. The results of these tests are logically ORed together and stored in the BIT Dynamic Status and BIT Latched Status registers.

Power-On Self-Test (POST)/Power-on BIT (PBIT)/Start-up BIT (SBIT)

This board features a power-on self-test that will do an accuracy check of each channel and report the results in the BIT Status register when complete. After power-on, the Power-on BIT Complete register should be checked to ensure that POST/PBIT/SBIT test is complete before reading the BIT Latched Status.

Continuous Background Built-In Test

The background Built-In-Test or Continuous BIT (CBIT) (“D2”) runs in the background where each channel is checked to a test accuracy of 0.2% FS. The testing is totally transparent to the user, requires no external programming, and has no effect on the operation of the module or card.

The technique used by the continuous background BIT (CBIT) test consists of an “add-2, subtract-1” counting scheme. The BIT counter is incremented by 2 when a BIT-fault is detected and decremented by 1 when there is no BIT fault detected and the BIT counter is greater than 0. When the BIT counter exceeds the (programmed) Background BIT Threshold value, the specific channel’s fault bit in the BIT status register will be set. Note, the interval at which BIT is performed is dependent and differs between module types. Rather than specifying the BIT Threshold as a “count”, the BIT Threshold is specified as a time in milliseconds. The module will convert the time specified to the BIT Threshold “count” based on the BIT interval for that module. The “add-2, subtract-1” counting scheme effectively filters momentary or intermittent anomalies by allowing them to “come and go“ before a BIT fault status or indication is flagged (e.g. BIT faults would register when sustained; i.e. at a ten second interval, not a 10-millisecond interval). This prevents spurious faults from registering valid such as those caused by EMI and/or dirty power causing false BIT faults. Putting more “weight” on errors (“add-2”) and less “weight” on subsequent passing results (subtract-1) will result in a BIT failure indication even if a channel “oscillates” between a pass and a fail state.

Initiate Built-In Test

The DS and DR modules supports an off-line Initiated Built-In Test (IBIT) (“D3”).

IBIT test starts an initiated BIT test that utilizes an internal stimulus to generate and test the full-scale positional range to a default test accuracy of 0.1% full scale range. IBIT test cycle is completed within 30 seconds and the result can be read from the BIT status registers when IBIT bit changes from 1 to 0.

Status and Interrupts

The DS (DR) Simulation Module provide registers that indicate faults or events. Refer to “Status and Interrupts Module Manual” for the Principle of Operation description.

Module Common Registers

The DS (DR) Simulation Module includes module common registers that provide access to module-level bare metal/FPGA revisions & compile times, unique serial number information, and temperature monitoring. Refer to “Module Common Registers Module Manual” for the detailed information.

REGISTER DESCRIPTIONS

The register descriptions provide the register name, Function Address Offset, Type, Data Range, Read or Write information, Initialized Value, a description of the function and, in most cases, a data table.

Control Registers

Power On/Off

Function: |

Turns on the selected channel and initiates output. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 - 0x0000 0007 (for supporting up to 3 channels) |

Read/Write: |

R/W |

Initialized Value: |

0x0000 0000 |

Operational Settings: |

To turn on the selected channel, set the bit to 1. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch3 |

Ch2 |

Ch1 |

DS Set Angle

Function: |

Sets synchro or resolver angle data in each channel for single-speed or multi-speed applications. |

Type: |

unsigned binary word (32-bit) |

Range: |

0 to 359.9999 degrees |

Read/Write: |

R/W |

Initialized Value: |

0° |

Operational Settings: |

For single-speed applications (Ratio=1), write a 32-bit integer to the corresponding channel D/S Data Register. WORD = Angle / (360/ 2^32) LSB is 360/232 or approximately 0.00000008382 degrees. The upper 24 bits define the angle, while the lower 8 bits are at zero. The module can automatically simulate two-speed applications (applies only to multiple channel modules. By entering a ratio in the DS Ratio Mode Ch ½ register, the fine channel (channel 2) will automatically output an angle proportional to the programmed coarse channel (channel 1) angle, multiplied by the ratio programmed. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

180 |

90 |

45 |

22.5 |

11.25 |

5.625 |

2.813 |

1.406 |

.703 |

.352 |

.176 |

.088 |

.044 |

.022 |

.011 |

.0055 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

.00274 |

.00137 |

.00068 |

.00034 |

.00017 |

.00008 |

.00004 |

.00002 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

DS Set Voltage

Function: |

Sets signal voltage “VL-L” to a corresponding register. |

Type: |

unsigned binary word (32-bit) |

Range: |

2-28 or 28-90 VL-L depending on model |

Read/Write: |

R/W |

Initialized Value: |

26 VL-L for low voltage modules and 90 VL-L for high voltage modules. |

Operational Settings: |

The output voltage is set with a resolution of 10 mVRMS. The setting is in integer decimal format. For example, if channel 1 Signal (VL-L) voltage is to be 11.8 VRMS, the set word to the corresponding register would be 1180. |

DS Expected Reference

Function: |

Sets reference voltage “VREF” to a corresponding register. |

Type: |

unsigned binary word (32-bit) |

Range: |

26 VREF for low voltage module or 115 VREF for high voltage module |

Read/Write: |

R/W |

Initialized Value: |

2 or 28 VL-L depending on model |

Operational Settings: |

The input voltage is set with a resolution of 10 mVRMS. The setting is in integer decimal format. For example, if channel 1 expected input REF voltage is 26.0 VRMS, the set word to the corresponding register would be 2600. |

DS Set Phase Offset

Function: |

Enables setting the phase (in degrees) of each channel to an offset of the Reference. |

Type: |

unsigned binary word (32-bit) |

Range: |

± 90° |

Read/Write: |

R/W |

Initialized Value: |

0° |

Operational Settings: |

The phase offset has 24-bit resolution put into the MSBs of the 32-bit word. Word = Phase / (360/2^32%). |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

180 |

90 |

45 |

22.5 |

11.25 |

5.625 |

2.813 |

1.406 |

.703 |

.352 |

.176 |

.088 |

.044 |

.022 |

.011 |

.0055 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

.00274 |

.00137 |

.00068 |

.00034 |

.00017 |

.00008 |

.00004 |

.00002 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

DS Output Mode (Ratio/Fixed)

Function: |

Enables selection of either ratiometric (ratio) or absolute (fixed) mode output voltages. |

Type: |

unsigned binary word (32-bit) |

Range: |

NA |

Read/Write: |

R/W |

Initialized Value: |

0 = Ratiometric |

Operational Settings: |

Ratiometric Mode, when selected, will cause the output signal voltage of the channel to vary with the input Reference Voltage. Fixed Mode, when selected, will cause the output signal voltage of the channel NOT to vary with the input Reference Voltage. Set corresponding channel bit to 0 for Ratiometric Mode. Set corresponding channel bit to 1 for Fixed Mode. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

Rotation Mode - Continuous or Start/Stop

Function: |

Sets channel for continuous or start/stop rotation. |

Type: |

unsigned binary word (32-bit) |

Range: |

NA |

Read/Write: |

R/W |

Initialized Value: |

NA |

Operational Settings: |

For continuous rotation, set the corresponding channel bit to 0. For rotation to cease at a designated stop angle, set the bit to 1. For 2-speed applications, only the odd (coarse) channel needs to be programmed (Ch1). |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

Stop Angle

Function: |

Stops rotation on selected channel when desired stop angle is reached. |

Type: |

unsigned binary word (32-bit) |

Range: |

0 to 359.9999 degrees |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

Word = Angle /(360/232) |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

180 |

90 |

45 |

22.5 |

11.25 |

5.625 |

2.813 |

1.406 |

.703 |

.352 |

.176 |

.088 |

.044 |

.022 |

.011 |

.0055 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

.00274 |

.00137 |

.00068 |

.00034 |

.00017 |

.00008 |

.00004 |

.00002 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Rotation Rate+_

Function: |

Sets rotation rate for selected channel. |

Type: |

signed binary word (32-bit) |

Range: |

+/-9.999 dps |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

Write a 2’s complement number representing the desired rotation rate. LSB = 0.015°/sec. For example, 12 RPS = (12 x 360°/0.015° = 288000 = 46500h), -12 RPS = (-12 x 360°/0.015° = -288000 = FFFB9B00h) |

Start Rotation

Function: |

Set this register after Rotation Rate register has been set. Will start rotating in continuous or start/stop rotation mode. |

Type: |

unsigned binary word (32-bit) |

Range: |

NA |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

To start rotation for the corresponding channel, write a 1 to the corresponding channel. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch3 |

Ch2 |

Ch1 |

Stop Rotation

Function: |

Stops a channel from rotating when a 1 is written to the corresponding bit location. |

Type: |

unsigned binary word (32-bit) |

Range: |

NA |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

To stop rotation for the corresponding channel, write a 1 to the corresponding channel. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Ch3 |

Ch2 |

Ch1 |

DS Ratio Mode Ch 1/2

Function: |

Sets the ratio from the coarse channel (channel 1) to the fine channel (channel 2). |

Type: |

unsigned binary word (32-bit) |

Range: |

1 to 255 |

Read/Write: |

R/W |

Initialized Value: |

1 |

Operational Settings: |

Set desired ratio between coarse (channel 1) and fine (channel 2) channels to be used as a two-speed channel. Example 1: In single speed mode, set this register to 1. This will allow channel 2 to be controlled by its own set angle register. Example 2: For a 36:1 ratio, set this register to 36. Now, the set angle for channel 2 will be equal to the set angle of channel 1, multiplied by 36. |

Measurement Registers

Wrap Angle

Function: |

Measures the output angle. |

Type: |

unsigned binary word (32-bit) |

Range: |

0-359.9999 |

Read/Write: |

R |

Initialized Value: |

0 |

Operational Settings: |

Measured angle in degrees = value * (360/232). |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

180 |

90 |

45 |

22.5 |

11.25 |

5.625 |

2.813 |

1.406 |

.703 |

.352 |

.176 |

.088 |

.044 |

.022 |

.011 |

.0055 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

.00274 |

.00137 |

.00068 |

.00034 |

.00017 |

.00008 |

.00004 |

.00002 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

Velocity

Function: |

Reads CW and CCW velocity of each channel in degrees per second (dps). |

Type: |

unsigned binary word (32-bit) |

Range: |

±10,000 dps |

Read/Write: |

R |

Initialized Value: |

0 |

Operational Settings: |

Velocity registers of each channel are read as a two’s complement word, with 0x7FFFh FFFF being maximum CW rotation, and 0x8000 0000 being maximum CCW rotation. LSB = 0.015°/sec. To convert a velocity word to dps: Velocity in dps = value * 0.015 (0.015 degree/second resolution) |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Measured Frequency

Function: |

Reads each channel’s input reference frequency. |

Type: |

unsigned binary word (32-bit) |

Range: |

Depends on model |

Read/Write: |

R |

Initialized Value: |

0 Hz |

Operational Settings: |

The input reference frequency is reported to a resolution of 1 Hz. The output is in integer decimal format. For example, if channel 1 input excitation is 400 Hz, the output measurement word from the corresponding register would be 400. |

Measured Signal Voltage

Function: |

Reads each channel’s output signal voltage VL-L. |

Type: |

32-bit unsigned integer |

Range: |

unsigned binary word (32-bit) |

Read/Write: |

R |

Initialized Value: |

0 VLL |

Operational Settings: |

The output voltage is reported to a resolution of 10 mVRMS. The output is in integer decimal format. For example, if channel 1 output signal voltage is 11.8 VRMS, the output measurement word from the corresponding register would be 1180. |

Measured Reference Voltage

Function: |

Reads each channel’s input signal reference voltage (VREF). |

Type: |

32-bit unsigned integer |

Range: |

unsigned binary word (32-bit) |

Read/Write: |

R |

Initialized Value: |

0 VREF on power up |

Operational Settings: |

The input voltage is reported to a resolution of 10 mVRMS. The output is in integer decimal format. For example, if channel 1 input VREF voltage is 26.0 VRMS, the output measurement word from the corresponding register would be 2600. |

Threshold Programming Registers

Signal Loss Threshold

Function: |

Programmable status threshold to indicate when the measured VLL falls below this value. |

Type: |

unsigned binary word (32-bit) |

Range: |

0 to 90 VL-L |

Read/Write: |

R/W |

Initialized Value: |

80% of default DS output voltage. |

Operational Settings: |

The signal loss detection circuitry can be tailored to report a signal loss (at Signal Loss Status register) at a user defined threshold. This threshold can be set to a resolution of 10 mVL-L. Program the threshold by writing the value of the voltage threshold in integer decimal format. For example, if Channel 1 signal loss voltage threshold is to be 7 VL-L, the programmed word to the corresponding register would be 700 (2BCh). |

Reference Loss Threshold

Function: |

Programmable status threshold to indicate when the measured VREF falls below this value. |

Type: |

unsigned binary word (32-bit) |

Range: |

0 to 115 Vrms |

Read/Write: |

R/W |

Initialized Value: |

80% of the default expected reference |

Operational Settings: |

The reference loss detection circuitry can be tailored to report a reference loss at a user defined threshold. This threshold can be set to a resolution of 10 mVrms. Program the threshold by writing the value of the voltage threshold in integer decimal format. For example, if channel 1 input reference loss voltage threshold is to be 20 VRMS, the programmed word to the corresponding register would be 2000 (7D0h). |

Test Registers

This module features a power-on self-test that will perform an accuracy check on each channel. In addition, two different tests, one on-line (CBIT) and one off-line (IBIT), can be selected. External reference voltage is not required for any of these tests.

Test Enabled

Function: |

Set bit in this register to enable associated Built-In Self-Test IBIT and CBIT. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 to 0x000D |

Read/Write: |

R/W |

Initialized Value: |

0x4 (CBIT Test Enabled) |

Operational Settings: |

BIT tests include an on-line (CBIT) test and an off-line (IBIT) test. Failures in the BIT tests are reflected in the BIT Status registers for the corresponding channels that fail. In addition, an interrupt (if enabled in the BIT Interrupt Enable register) can be triggered when the BIT testing detects a failure. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

IBIT Test D |

CBIT Test 1 |

0 |

0 |

Test CBIT Verify

Function: |

Allows user to verify if the CBIT test is running. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

User can write any value to this register. If CBIT test is running, after a minimum of 10ms the value read back will be 0x0000 0055, otherwise the value read back will be the value written. |

Module Common Registers

Refer to “Module Common Registers Module Manual” for the register descriptions.

Status and Interrupt Registers

The DS (DR) Simulation Module provides status registers for BIT, Signal Loss, Reference Loss, Phase Lock, DS Rotation and Overcurrent.

Channel Status Enabled

Function: |

Determines whether to update the status for the channels. The feature can be used to “mask' status bits of unused channels in status registers that are bitmapped by channel |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 - 0x0000 FFFF |

Read/Write: |

R/W |

Initialized Value: |

0x0000 FFFF |

Operational Settings: |

When the bit corresponding to a given channel in the Channel Status Enabled register is not enabled (0), the statuses will be masked and report “0” or “no failure”. This applies to all statuses that are bitmapped by channel (BIT Status, Signal Loss Status, Reference Loss Status, Phase Lock Status, DS Rotation Status and Overcurrent Status). When the bit corresponding to a given channel is enabled (1), it will allow the statuses for that channel to be updated. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

BIT Status

There are four registers associated with the BIT Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s BIT error. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 0007 |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

BIT Dynamic Status |

|||||||||||||||

BIT Latched Status |

|||||||||||||||

BIT Interrupt Enable |

|||||||||||||||

BIT Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

CH3 |

CH2 |

CH1 |

Signal Loss Status

There are four registers associated with the Signal Loss Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s Signal Loss error. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 0007 |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Signal Loss Dynamic Status |

|||||||||||||||

Signal Loss Latched Status |

|||||||||||||||

Signal Loss Interrupt Enable |

|||||||||||||||

Signal Loss Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

CH3 |

CH2 |

CH1 |

Reference Loss Status

There are four registers associated with the Reference Loss Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s Reference Fault Low error. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 0007 |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Reference Loss Dynamic Status |

|||||||||||||||

Reference Loss Latched Status |

|||||||||||||||

Reference Loss Interrupt Enable |

|||||||||||||||

Reference Loss Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

CH3 |

CH2 |

CH1 |

Phase Lock Status

There are four registers associated with the Phase Lock Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s Phase Lock error. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 0007 |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Phase Lock Dynamic Status |

|||||||||||||||

Phase Lock Latched Status |

|||||||||||||||

Phase Lock Interrupt Enable |

|||||||||||||||

Phase Lock Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

CH3 |

CH2 |

CH1 |

DS Rotation Status

There are four registers associated with the DS Rotation Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s DS Rotation error. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 0007 |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

DS Rotation Dynamic Status |

|||||||||||||||

DS Rotation Latched Status |

|||||||||||||||

DS Rotation Interrupt Enable |

|||||||||||||||

DS Rotation Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

CH3 |

CH2 |

CH1 |

Overcurrent Status

There are four registers associated with the Overcurrent Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Function: |

Sets the corresponding bit associated with the channel’s Overcurrent error. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0x0000 0007 |

Read/Write: |

R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt) |

Initialized Value: |

0 |

Overcurrent Dynamic Status |

|||||||||||||||

Overcurrent Latched Status |

|||||||||||||||

Overcurrent Interrupt Enable |

|||||||||||||||

Overcurrent Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

CH3 |

CH2 |

CH1 |

Interrupt Vector and Steering

Edit this on GitLab

When interrupts are enabled, the interrupt vector associated with the specific interrupt can be programmed (typically with a unique number/identifier) such that it can be utilized in the Interrupt Service Routine (ISR) to identify the type of interrupt. When an interrupt occurs, the contents of the Interrupt Vector registers is reported as part of the interrupt mechanism. In addition to specifying the interrupt vector, the interrupt can be directed (“steered”) to the native bus or to the application running on the onboard ARM processor.

|

Note

|

The Interrupt Vector and Interrupt Steering registers are mapped to the Motherboard Common Memory and these registers are associated with the Module Slot position (refer to Function Register Map). |

Interrupt Vector

Function: |

Set an identifier for the interrupt. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

When an interrupt occurs, this value is reported as part of the interrupt mechanism. |

Interrupt Steering

Function: |

Sets where to direct the interrupt. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

See table Read/Write: R/W |

Initialized Value: |

0 |

Operational Settings: |

When an interrupt occurs, the interrupt is sent as specified: |

Direct Interrupt to VME |

1 |

Direct Interrupt to ARM Processor (via SerDes) (Custom App on ARM or NAI Ethernet Listener App) |

2 |

Direct Interrupt to PCIe Bus |

5 |

Direct Interrupt to cPCI Bus |

6 |

FUNCTION REGISTER MAP

Key:

Bold Italic |

= Configuration/Control |

Bold Underline |

= Measurement/Status |

*When an event is detected, the bit associated with the event is set in this register and will remain set until the user clears the event bit. Clearing the bit requires writing a 1 back to the specific bit that was set when read (i.e. write-1-to-clear, writing a '1' to a bit set to '1' will set the bit to '0').

~ Data is always in Floating Point.

Control Registers

Addr (Hex) |

Name |

Read/Write |

0x0250 |

Power On/Off++ |

R/W |

++After power-on, Power-on BIT Complete should be checked before reading the BIT Latched Status.

Addr (Hex) |

Name |

Read/Write |

0x1000 |

DS Set Angle Ch 1 |

R/W |

0x1004 |

DS Set Angle Ch 2 |

R/W |

0x1008 |

DS Set Angle Ch 3 |

R/W. |

Addr (Hex) |

Name |

Read/Write |

0x1010 |

DS Set Voltage Ch 1 |

R/W |

0x1014 |

DS Set Voltage Ch 2 |

R/W |

0x1018 |

DS Set Voltage Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1020 |

DS Expected Reference Ch 1 |

R/W |

0x1024 |

DS Expected Reference Ch 2 |

R/W |

0x1028 |

DS Expected Reference Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1030 |

DS Set Phase Offset Ch 1 |

R/W |

0x1034 |

DS Set Phase Offset Ch 2 |

R/W |

0x1038 |

DS Set Phase Offset Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1040 |

DS Output Mode (Ratio/Fixed) Ch 1 |

R/W |

0x1044 |

DS Output Mode (Ratio/Fixed) Ch 2 |

R/W |

0x1048 |

DS Output Mode (Ratio/Fixed) Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x10F0 |

Rotation Mode - Continuous Start/Stop Ch 1 |

R/W |

0x10F4 |

Rotation Mode - Continuous Start/Stop Ch 2 |

R/W |

0x10F8 |

Rotation Mode - Continuous Start/Stop Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1100 |

Stop Angle Ch 1 |

R/W |

0x1104 |

Stop Angle Ch 2 |

R/W |

0x1108 |

Stop Angle Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1110 |

Rotation Rate Ch 1 |

R/W |

0x1114 |

Rotation Rate Ch 2 |

R/W |

0x1118 |

Rotation Rate Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1120 |

Start Rotation Ch 1-3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1124 |

Stop Rotation Rate Ch 1-3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1140 |

DS Ratio Mode Ch 1/2 |

R/W |

Measurement Registers

Addr (Hex) |

Name |

Read/Write |

0x1050 |

Wrap Angle Ch 1 |

R |

0x1054 |

Wrap Angle Ch 2 |

R |

0x1058 |

Wrap Angle Ch 3 |

R |

Addr (Hex) |

Name |

Read/Write |

0x1160 |

Velocity Ch 1 |

R |

0x1164 |

Velocity Ch 2 |

R |

0x1168 |

Velocity Ch 3 |

R |

Addr (Hex) |

Name |

Read/Write |

0x1070 |

Measured Frequency Ch 1 |

R |

0x1074 |

Measured Frequency Ch 2 |

R |

0x1078 |

Measured Frequency Ch 3 |

R |

Addr (Hex) |

Name |

Read/Write |

0x1080 |

Measured Signal Voltage Ch 1 |

R |

0x1084 |

Measured Signal Voltage Ch 2 |

R |

0x1088 |

Measured Signal Voltage Ch 3 |

R |

Addr (Hex) |

Name |

Read/Write |

0x1090 |

Measured Reference Voltage Ch 1 |

R |

0x1094 |

Measured Reference Voltage Ch 2 |

R |

0x1098 |

Measured Reference Voltage Ch 3 |

R |

Addr (Hex) |

Name |

Read/Write |

0x10A0 |

Measured Current Ch 1 |

R |

0x10A4 |

Measured Current Ch 2 |

R |

0x10A8 |

Measured Current Ch 3 |

R |

Threshold Programming Registers

Addr (Hex) |

Name |

Read/Write |

0x10B0 |

Signal Loss Threshold Ch 1 |

R/W |

0x10B4 |

Signal Loss Threshold Ch 2 |

R/W |

0x10B8 |

Signal Loss Threshold Ch 3 |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x10C0 |

Reference Loss Threshold Ch 1 |

R/W |

0x10C4 |

Reference Loss Threshold Ch 2 |

R/W |

0x10C8 |

Reference Loss Threshold Ch 3 |

R/W |

Module Common Registers

Refer to “Module Common Registers Module Manual” for the Module Common Registers Function Register Map.

Status Registers

Bit Status

Addr (Hex) |

Name |

Read/Write |

0x0800 |

Dynamic Status |

R |

0x0804 |

Latched Status* |

R/W |

0x0808 |

Interrupt Enable |

R/W |

0x080C |

Set Edge/Level Interrupt |

R/W |

Signal Loss Status

Addr (Hex) |

Name |

Read/Write |

0x0810 |

Dynamic Status |

R |

0x0814 |

Latched Status* |

R/W |

0x0818 |

Interrupt Enable |

R/W |

0x081C |

Set Edge/Level Interrupt |

R/W |

Reference Loss Status

Addr (Hex) |

Name |

Read/Write |

0x0820 |

Dynamic Status |

R |

0x0824 |

Latched Status* |

R/W |

0x0828 |

Interrupt Enable |

R/W |

0x082C |

Set Edge/Level Interrupt |

R/W |

Phase Lock Status

Addr (Hex) |

Name |

Read/Write |

0x0830 |

Dynamic Status |

R |

0x0834 |

Latched Status* |

R/W |

0x0838 |

Interrupt Enable |

R/W |

0x083C |

Set Edge/Level Interrupt |

R/W |

DS Rotation Status

Addr (Hex) |

Name |

Read/Write |

0x0840 |

Dynamic Status |

R |

0x0844 |

Latched Status* |

R/W |

0x0848 |

Interrupt Enable |

R/W |

0x084C |

Set Edge/Level Interrupt |

R/W |

Overcurrent Status

Addr (Hex) |

Name |

Read/Write |

0x0850 |

Dynamic Status |

R |

0x0854 |

Latched Status* |

R/W |

0x0858 |

Interrupt Enable |

R/W |

0x085C |

Set Edge/Level Interrupt |

R/W |

Interrupt Registers

The Interrupt Vector and Interrupt Steering registers are located on the Motherboard Memory Space and do not require any Module Address Offsets. These registers are accessed using the absolute addresses listed in the table below.

Addr (Hex) |

Name |

Read/Write |

0x0500 |

Module 1 Interrupt Vector 1 - BIT |

R/W |

0x0504 |

Module 1 Interrupt Vector 2 - Signal Loss |

R/W |

0x0508 |

Module 1 Interrupt Vector 3 - Reference Loss |

R/W |

0x050C |

Module 1 Interrupt Vector 4 - Phase Lock |

R/W |

0x0510 |

Module 1 Interrupt Vector 5 - DS Rotation |

R/W |

0x0514 |

Module 1 Interrupt Vector 6 - Overcurrent |

R/W |

0x0518 to 0x057C |

Module 1 Interrupt Vector 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0600 |

Module 1 Interrupt Steering 1 - BIT |

R/W |

0x0604 |

Module 1 Interrupt Steering 2 - Signal Loss |

R/W |

0x0608 |

Module 1 Interrupt Steering 3 - Reference Loss |

R/W |

0x060C |

Module 1 Interrupt Steering 4 - Phase Lock |

R/W |

0x0610 |

Module 1 Interrupt Steering 5 - DS Rotation |

R/W |

0x0614 |

Module 1 Interrupt Steering 6 - Overcurrent |

R/W |

0x0618 to 0x067C |

Module 1 Interrupt Steering 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0700 |

Module 2 Interrupt Vector 1 - BIT |

R/W |

0x0704 |

Module 2 Interrupt Vector 2 - Signal Loss |

R/W |

0x0708 |

Module 2 Interrupt Vector 3 - Reference Loss |

R/W |

0x070C |

Module 2 Interrupt Vector 4 - Phase Lock |

R/W |

0x0710 |

Module 2 Interrupt Vector 5 - DS Rotation |

R/W |

0x0714 |

Module 2 Interrupt Vector 6 - Overcurrent |

R/W |

0x0718 to 0x077C |

Module 2 Interrupt Vector 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0800 |

Module 2 Interrupt Steering 1 - BIT |

R/W |

0x0804 |

Module 2 Interrupt Steering 2 - Signal Loss |

R/W |

0x0808 |

Module 2 Interrupt Steering 3 - Reference Loss |

R/W |

0x080C |

Module 2 Interrupt Steering 4 - Phase Lock |

R/W |

0x0810 |

Module 2 Interrupt Steering 5 - DS Rotation |

R/W |

0x0814 |

Module 2 Interrupt Steering 6 - Overcurrent |

R/W |

0x0818 to 0x087C |

Module 2 Interrupt Steering 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0900 |

Module 3 Interrupt Vector 1 - BIT |

R/W |

0x0904 |

Module 3 Interrupt Vector 2 - Signal Loss |

R/W |

0x0908 |

Module 3 Interrupt Vector 3 - Reference Loss |

R/W |

0x090C |

Module 3 Interrupt Vector 4 - Phase Lock |

R/W |

0x0910 |

Module 3 Interrupt Vector 5 - DS Rotation |

R/W |

0x0914 |

Module 3 Interrupt Vector 6 - Overcurrent |

R/W |

0x0918 to 0x097C |

Module 3 Interrupt Vector 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0A00 |

Module 3 Interrupt Steering 1 - BIT |

R/W |

0x0A04 |

Module 3 Interrupt Steering 2 - Signal Loss |

R/W |

0x0A08 |

Module 3 Interrupt Steering 3 - Reference Loss |

R/W |

0x0A0C |

Module 3 Interrupt Steering 4 - Phase Lock |

R/W |

0x0A10 |

Module 3 Interrupt Steering 5 - DS Rotation |

R/W |

0x0A14 |

Module 3 Interrupt Steering 6 - Overcurrent |

R/W |

0x0A18 to 0x0A7C |

Module 3 Interrupt Steering 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0B00 |

Module 4 Interrupt Vector 1 - BIT |

R/W |

0x0B04 |

Module 4 Interrupt Vector 2 - Signal Loss |

R/W |

0x0B08 |

Module 4 Interrupt Vector 3 - Reference Loss |

R/W |

0x0B0C |

Module 4 Interrupt Vector 4 - Phase Lock |

R/W |

0x0B10 |

Module 4 Interrupt Vector 5 - DS Rotation |

R/W |

0x0B14 |

Module 4 Interrupt Vector 6 - Overcurrent |

R/W |

0x0B18 to 0x0B7C |

Module 4 Interrupt Vector 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0C00 |

Module 4 Interrupt Steering 1 - BIT |

R/W |

0x0C04 |

Module 4 Interrupt Steering 2 - Signal Loss |

R/W |

0x0C08 |

Module 4 Interrupt Steering 3 - Reference Loss |

R/W |

0x0C0C |

Module 4 Interrupt Steering 4 - Phase Lock |

R/W |

0x0C10 |

Module 4 Interrupt Steering 5 - DS Rotation |

R/W |

0x0C14 |

Module 4 Interrupt Steering 6 - Overcurrent |

R/W |

0x0C18 to 0x0C7C |

Module 4 Interrupt Steering 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0D00 |

Module 5 Interrupt Vector 1 - BIT |

R/W |

0x0D04 |

Module 5 Interrupt Vector 2 - Signal Loss |

R/W |

0x0D08 |

Module 5 Interrupt Vector 3 - Reference Loss |

R/W |

0x0D0C |

Module 5 Interrupt Vector 4 - Phase Lock |

R/W |

0x0D10 |

Module 5 Interrupt Vector 5 - DS Rotation |

R/W |

0x0D14 |

Module 5 Interrupt Vector 6 - Overcurrent |

R/W |

0x0D18 to 0x0D7C |

Module 5 Interrupt Vector 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0E00 |

Module 5 Interrupt Steering 1 - BIT |

R/W |

0x0E04 |

Module 5 Interrupt Steering 2 - Signal Loss |

R/W |

0x0E08 |

Module 5 Interrupt Steering 3 - Reference Loss |

R/W |

0x0E0C |

Module 5 Interrupt Steering 4 - Phase Lock |

R/W |

0x0E10 |

Module 5 Interrupt Steering 5 - DS Rotation |

R/W |

0x0E14 |

Module 5 Interrupt Steering 6 - Overcurrent |

R/W |

0x0E18 to 0x0E7C |

Module 5 Interrupt Steering 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x0F00 |

Module 6 Interrupt Vector 1 - BIT |

R/W |

0x0F04 |

Module 6 Interrupt Steering 2 - Signal Loss |

R/W |

0x0F08 |

Module 6 Interrupt Steering 3 - Reference Loss |

R/W |

0x0F0C |

Module 6 Interrupt Steering 4 - Phase Lock |

R/W |

0x0F10 |

Module 6 Interrupt Steering 5 - DS Rotation |

R/W |

0x0F14 |

Module 6 Interrupt Steering 6 - Overcurrent |

R/W |

0x0F18 to 0x0F7C |

Module 6 Interrupt Vector 7-32 - Reserved |

R/W |

Addr (Hex) |

Name |

Read/Write |

0x1000 |

Module 6 Interrupt Steering 1 - BIT |

R/W |

0x1004 |

Module 6 Interrupt Steering 2 - Signal Loss |

R/W |

0x1008 |

Module 6 Interrupt Steering 3 - Reference Loss |

R/W |

0x100C |

Module 6 Interrupt Steering 4 - Phase Lock |

R/W |

0x1010 |

Module 6 Interrupt Steering 5 - DS Rotation |

R/W |

0x1014 |

Module 6 Interrupt Steering 6 - Overcurrent |

R/W |

0x1018 to 0x107C |

Module 6 Interrupt Steering 7-32 - Reserved |

R/W |

APPENDIX: PINOUT DETAILS

Pinout details (for reference) are shown below, with respect to DATAIO. Additional information on pin-outs can be found in the Motherboard Operational Manuals.

Module Signal (Ref Only) |

44-Pin I/O |

50-Pin I/O (Mod Slot 1-J3) |

50-Pin I/O (Mod Slot 2-J4) |

50-Pin I/O (Mod Slot 3-J3) |

50-Pin I/O (Mod Slot 3-J4) |

DS-1CH 8VA (DSX, DRX) |

DS-2CH (DSX, DRX) |

DS-3CH (DSX, DRX) |

DATIO1 |

2 |

10 |

1 |

2 |

S1-SNS-CH1 |

S1-CH1 |

S3-CH1 |

|

DATIO2 |

24 |

35 |

26 |

27 |

S3-SNS-CH1 |

RHI-CH1 |

RHI-CH1 |

|

DATIO3 |

3 |

11 |

2 |

3 |

S1-SNS-CH1 |

S3-SNS-CH1 |

||

DATIO4 |

25 |

36 |

27 |

28 |

RLO-CH1 |

RLO-CH1 |

||

DATIO5 |

5 |

13 |

4 |

5 |

S1-CH1 |

S3-CH1 |

S1-CH1 |

|

DATIO6 |

27 |

38 |

29 |

30 |

S3-CH1 |

S2-CH1 |

S1-CH2 |

|

DATIO7 |

7 |

14 |

5 |

6 |

S3-SNS-CH1 |

S2-SNS-CH1 |

||

DATIO8 |

29 |

39 |

30 |

31 |

S2-SNS-CH1 |

RHI-CH2 |

||

DATIO9 |

8 |

15 |

6 |

7 |

N/C (SIN-PWM-CH) |

S2-CH1 |

||

DATIO10 |

30 |

40 |

31 |

32 |

N/C (SIN-PWM) |

S4-SNS-CH1 |

RLO-CH2 |

|

DATIO11 |

10 |

17 |

8 |

9 |

N/C (COS-PWM-CH1) |

S4-CH1 |

||

DATIO12 |

32 |

42 |

33 |

34 |

S4-CH1 |

S3-CH2 |

||

DATIO13 |

12 |

18 |

9 |

17 |

S2-SNS-CH1 |

S4-CH2 |

S3-CH3 |

|

DATIO14 |

34 |

43 |

34 |

42 |

S4-SNS-CH1 |

S1-CH2 |

RHI-CH3 |

|

DATIO15 |

13 |

19 |

10 |

18 |

S4-SNS-CH2 |

S3-SNS-CH3 |

||

DATIO16 |

35 |

44 |

35 |

43 |

N/C (COS-PWM) |

S1-SNS-CH2 |

RLO-CH3 |

|

DATIO17 |

15 |

21 |

12 |

20 |

S2-CH1 |

S2-CH2 |

S1-CH3 |

|

DATIO18 |

37 |

46 |

37 |

45 |

S4-CH1 |

S3-CH2 |

S2-CH2 |

|

DATIO19 |

17 |

22 |

13 |

21 |

S2-SNS-CH2 |

S4-CH3 |

||

DATIO20 |

39 |

47 |

38 |

46 |

S3-SNS-CH2 |

S4-CH2 |

||

DATIO21 |

18 |

23 |

14 |

22 |

N/C (COS-PWM-CH2) |

S4-SNS-CH3 |

||

DATIO22 |

40 |

48 |

39 |

47 |

RHI-CH2 |

S4-SNS-CH2 |

||

DATIO23 |

20 |

25 |

16 |

24 |

RHI-CH1 |

N/C (SIN-PWM-CH2) |

S2-CH3 |

|

DATIO24 |

42 |

50 |

41 |

49 |

RLO-CH1 |

RLO-CH2 |

||

DATIO25 |

4 |

12 |

3 |

4 |

S1-SNS-CH1 |

|||

DATIO26 |

26 |

37 |

28 |

29 |

S1-SNS-CH2 |

|||

DATIO27 |

9 |

16 |

7 |

8 |

S4-SNS-CH1 |

|||

DATIO28 |

31 |

41 |

32 |

33 |

S3-SNS-CH2 |

|||

DATIO29 |

14 |

20 |

11 |

19 |

S1-SNS-CH3 |

|||

DATIO30 |

36 |

45 |

36 |

44 |

S2-SNS-CH2 |

|||

DATIO31 |

19 |

24 |

15 |

23 |

S2-SNS-CH3 |

|||

DATIO32 |

41 |

49 |

40 |

48 |

||||

DATIO33 |

6 |

|||||||

DATIO34 |

28 |

|||||||

DATIO35 |

11 |

|||||||

DATIO36 |

33 |

|||||||

DATIO37 |

16 |

|||||||

DATIO38 |

38 |

|||||||

DATIO39 |

21 |

|||||||

DATIO40 |

43 |

|||||||

N/A |

N/C |

Not connected. Note that bold signals in parentheses (XXXXX) are for internal use only |

REVISION HISTORY

Motherboard Manual - DS1-DSN Revision History |

||

Revision |

Revision Date |

Description |

C |

2022-07-08 |

ECO C09252, transition to docbuilder format. Replaced 'Specifications' section with 'Data Sheet' section. Pg.6, defined Number of Channels. Pg.6, added additional Accuracy details for DSL/DRL/DSM/DRM. Pg.6, defined Output Voltage specs. Pg.6, defined Output Load specs and added derating note. Pg. 6, removed '3-channel HV model only' references from rotation specs. Pg. 7, added Current specs for 2 CH LV/3 CH LV modules. Pg.9, added description of Transformation Ratio to Principle of Operation. Pg.9, added power-on self-test/CBIT/IBIT details to 'Diagnostic Capability'. Pg.10, added Power On/Off register description. Pg.16, added Test Registers. Pg.17, added Channel Status Enabled register description. Pg.21, added Power On/Off register offset. Pg.23, added Channel Status and Test register offsets. Pg.26, added Appendix: Pin-Out Details. |

C1 |

2024-06-06 |

ECO C11593, pg.6, updated Rotational Mode details. Pg.9/16/22, added module common registers manual reference. Pg.12, updated Rotation Rate type (from unsigned to signed). Pg.12, updated Rotation Rate range (from +-/10K to +/- 9,999). Pg.12, updated negative rotation value in Rotation Rate op settings to full 32-bit value. Pg.17, changed Channel Status Enabled Range/Init Value to 7. Pg.18, changed Reference Loss Status Range to 7. Pg.19/23-25, changed Phase Lock to Phase Lock Loss. Pg.19, changed Phase Lock Loss/DS Rotation/Overcurrent Status Range to 7. |

C2 |

2024-08-12 |

ECO C11768, pg.6, combined non power/current module specific specs into single table; added frequency range. |

DOCS.NAII REVISIONS

Revision Date |

Description |

2025-03-11 |

Updated module pinout table to add module I/O pinouts for 44- & 50-pin connectors. |

2025-03-28 |

Updated Output Mode & Rotation Mode register bit mapping (changed bits D2-D0 from Ch3/Ch2/Ch1 to 0/0/D); added bit map to Stop Angle register. |

STATUS AND INTERRUPTS

Edit this on GitLab

Status registers indicate the detection of faults or events. The status registers can be channel bit-mapped or event bit-mapped. An example of a channel bit-mapped register is the BIT status register, and an example of an event bit-mapped register is the FIFO status register.

For those status registers that allow interrupts to be generated upon the detection of the fault or the event, there are four registers associated with each status: Dynamic, Latched, Interrupt Enabled, and Set Edge/Level Interrupt.

Dynamic Status: The Dynamic Status register indicates the current condition of the fault or the event. If the fault or the event is momentary, the contents in this register will be clear when the fault or the event goes away. The Dynamic Status register can be polled, however, if the fault or the event is sporadic, it is possible for the indication of the fault or the event to be missed.

Latched Status: The Latched Status register indicates whether the fault or the event has occurred and keeps the state until it is cleared by the user. Reading the Latched Status register is a better alternative to polling the Dynamic Status register because the contents of this register will not clear until the user commands to clear the specific bit(s) associated with the fault or the event in the Latched Status register. Once the status register has been read, the act of writing a 1 back to the applicable status register to any specific bit (channel/event) location will “clear” the bit (set the bit to 0). When clearing the channel/event bits, it is strongly recommended to write back the same bit pattern as read from the Latched Status register. For example, if the channel bit-mapped Latched Status register contains the value 0x0000 0005, which indicates fault/event detection on channel 1 and 3, write the value 0x0000 0005 to the Latched Status register to clear the fault/event status for channel 1 and 3. Writing a “1” to other channels that are not set (example 0x0000 000F) may result in incorrectly “clearing” incoming faults/events for those channels (example, channel 2 and 4).

Interrupt Enable: If interrupts are preferred upon the detection of a fault or an event, enable the specific channel/event interrupt in the Interrupt Enable register. The bits in Interrupt Enable register map to the same bits in the Latched Status register. When a fault or event occurs, an interrupt will be fired. Subsequent interrupts will not trigger until the application acknowledges the fired interrupt by clearing the associated channel/event bit in the Latched Status register. If the interruptible condition is still persistent after clearing the bit, this may retrigger the interrupt depending on the Edge/Level setting.

Set Edge/Level Interrupt: When interrupts are enabled, the condition on retriggering the interrupt after the Latch Register is “cleared” can be specified as “edge” triggered or “level” triggered. Note, the Edge/Level Trigger also affects how the Latched Register value is adjusted after it is “cleared” (see below).

-

Edge triggered: An interrupt will be retriggered when the Latched Status register change from low (0) to high (1) state. Uses for edge-triggered interrupts would include transition detections (Low-to-High transitions, High-to-Low transitions) or fault detections. After “clearing” an interrupt, another interrupt will not occur until the next transition or the re-occurrence of the fault again.

-

Level triggered: An interrupt will be generated when the Latched Status register remains at the high (1) state. Level-triggered interrupts are used to indicate that something needs attention.

Interrupt Vector and Steering

When interrupts are enabled, the interrupt vector associated with the specific interrupt can be programmed with a unique number/identifier defined by the user such that it can be utilized in the Interrupt Service Routine (ISR) to identify the type of interrupt. When an interrupt occurs, the contents of the Interrupt Vector registers is reported as part of the interrupt mechanism. In addition to specifying the interrupt vector, the interrupt can be directed (“steered”) to the native bus or to the application running on the onboard ARM processor.

Interrupt Trigger Types

In most applications, limiting the number of interrupts generated is preferred as interrupts are costly, thus choosing the correct Edge/Level interrupt trigger to use is important.

Example 1: Fault detection

This example illustrates interrupt considerations when detecting a fault like an “open” on a line. When an “open” is detected, the system will receive an interrupt. If the “open” on the line is persistent and the trigger is set to “edge”, upon “clearing” the interrupt, the system will not regenerate another interrupt. If, instead, the trigger is set to “level”, upon “clearing” the interrupt, the system will re-generate another interrupt. Thus, in this case, it will be better to set the trigger type to “edge”.

Example 2: Threshold detection

This example illustrates interrupt considerations when detecting an event like reaching or exceeding the “high watermark” threshold value. In a communication device, when the number of elements received in the FIFO reaches the high-watermark threshold, an interrupt will be generated. Normally, the application would read the count of the number of elements in the FIFO and read this number of elements from the FIFO. After reading the FIFO data, the application would “clear” the interrupt. If the trigger type is set to “edge”, another interrupt will be generated only if the number of elements in FIFO goes below the “high watermark” after the “clearing” the interrupt and then fills up to reach the “high watermark” threshold value. Since receiving communication data is inherently asynchronous, it is possible that data can continue to fill the FIFO as the application is pulling data off the FIFO. If, at the time the interrupt is “cleared”, the number of elements in the FIFO is at or above the “high watermark”, no interrupts will be generated. In this case, it will be better to set the trigger type to “level”, as the purpose here is to make sure that the FIFO is serviced when the number of elements exceeds the high watermark threshold value. Thus, upon “clearing” the interrupt, if the number of elements in the FIFO is at or above the “high watermark” threshold value, another interrupt will be generated indicating that the FIFO needs to be serviced.

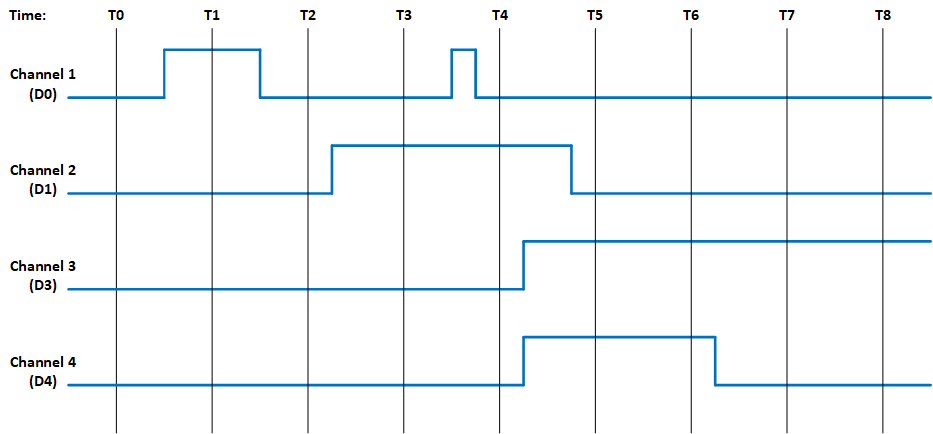

Dynamic and Latched Status Registers Examples

The examples in this section illustrate the differences in behavior of the Dynamic Status and Latched Status registers as well as the differences in behavior of Edge/Level Trigger when the Latched Status register is cleared.

Figure 1. Example of Module’s Channel-Mapped Dynamic and Latched Status States

| No Clearing of Latched Status | Clearing of Latched Status (Edge-Triggered) | Clearing of Latched Status(Level-Triggered) | ||||

|---|---|---|---|---|---|---|

Time |

Dynamic Status |

Latched Status |

Action |

Latched Status |

Action |

Latched |

T0 |

0x0 |

0x0 |

Read Latched Register |

0x0 |

Read Latched Register |

0x0 |

T1 |

0x1 |

0x1 |

Read Latched Register |

0x1 |

0x1 |

|

T1 |

0x1 |

0x1 |

Write 0x1 to Latched Register |

Write 0x1 to Latched Register |

||

T1 |

0x1 |

0x1 |

0x0 |

0x1 |

||

T2 |

0x0 |

0x1 |

Read Latched Register |

0x0 |

Read Latched Register |

0x1 |

T2 |

0x0 |

0x1 |

Read Latched Register |

0x0 |

Write 0x1 to Latched Register |

|

T2 |

0x0 |

0x1 |

Read Latched Register |

0x0 |

0x0 |

|

T3 |

0x2 |

0x3 |

Read Latched Register |

0x2 |

Read Latched Register |

0x2 |

T3 |

0x2 |

0x3 |

Write 0x2 to Latched Register |

Write 0x2 to Latched Register |

||

T3 |

0x2 |

0x3 |

0x0 |

0x2 |

||

T4 |

0x2 |

0x3 |

Read Latched Register |

0x1 |

Read Latched Register |

0x3 |

T4 |

0x2 |

0x3 |

Write 0x1 to Latched Register |

Write 0x3 to Latched Register |

||

T4 |

0x2 |

0x3 |

0x0 |

0x2 |

||

T5 |

0xC |

0xF |

Read Latched Register |

0xC |

Read Latched Register |

0xE |

T5 |

0xC |

0xF |

Write 0xC to Latched Register |

Write 0xE to Latched Register |

||

T5 |

0xC |

0xF |

0x0 |

0xC |

||

T6 |

0xC |

0xF |

Read Latched Register |

0x0 |

Read Latched |

0xC |

T6 |

0xC |

0xF |

Read Latched Register |

0x0 |

Write 0xC to Latched Register |

|

T6 |

0xC |

0xF |

Read Latched Register |

0x0 |

0xC |

|

T7 |

0x4 |

0xF |

Read Latched Register |

0x0 |

Read Latched Register |

0xC |

T7 |

0x4 |

0xF |

Read Latched Register |

0x0 |

Write 0xC to Latched Register |

|

T7 |

0x4 |

0xF |

Read Latched Register |

0x0 |

0x4 |

|

T8 |

0x4 |

0xF |

Read Latched Register |

0x0 |

Read Latched Register |

0x4 |

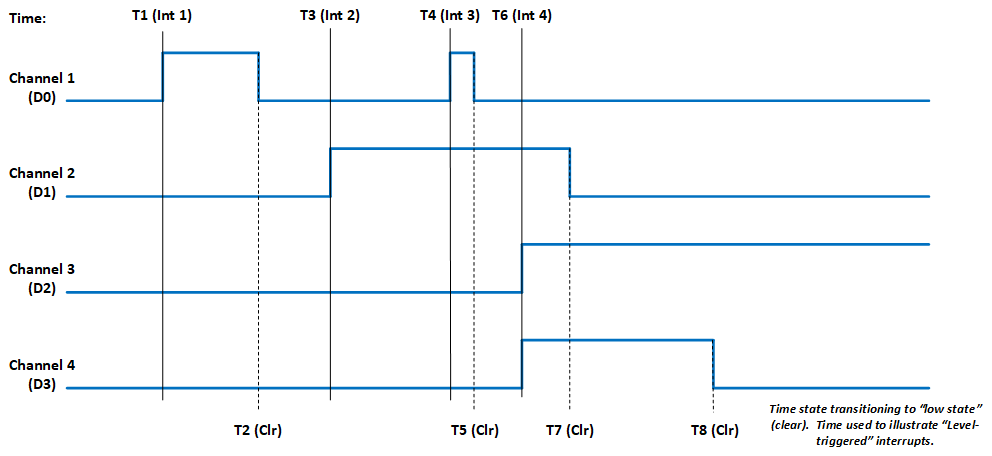

Interrupt Examples

The examples in this section illustrate the interrupt behavior with Edge/Level Trigger.

Figure 2. Illustration of Latched Status State for Module with 4-Channels with Interrupt Enabled

Time |

Latched Status (Edge-Triggered – Clear Multi-Channel) |

Latched Status (Edge-Triggered – Clear Single Channel) |

Latched Status (Level-Triggered – Clear Multi-Channel) |

|||

Time |

Action |

Latched |

Action |

Latched |

Action |

Latched |

T1 (Int 1) |

Interrupt Generated Read Latched Registers |

0x1 |

Interrupt Generated Read Latched Registers |

0x1 |

Interrupt Generated Read Latched Registers |

0x1 |

T1 (Int 1) |

Write 0x1 to Latched Register |

Write 0x1 to Latched Register |

Write 0x1 to Latched Register |

|||

T1 (Int 1) |

0x0 |

0x0 |

Interrupt re-triggers Note, interrupt re-triggers after each clear until T2. |

0x1 |

||

T3 (Int 2) |

Interrupt Generated Read Latched Registers |

0x2 |

Interrupt Generated Read Latched Registers |

0x2 |

Interrupt Generated Read Latched Registers |

0x2 |

T3 (Int 2) |

Write 0x2 to Latched Register |

Write 0x2 to Latched Register |

Write 0x2 to Latched Register |

|||

T3 (Int 2) |

0x0 |

0x0 |

Interrupt re-triggers Note, interrupt re-triggers after each clear until T7. |

0x2 |

||

T4 (Int 3) |

Interrupt Generated Read Latched Registers |

0x1 |

Interrupt Generated Read Latched Registers |

0x1 |

Interrupt Generated Read Latched Registers |

0x3 |

T4 (Int 3) |

Write 0x1 to Latched Register |

Write 0x1 to Latched Register |

Write 0x3 to Latched Register |

|||

T4 (Int 3) |

0x0 |

0x0 |

Interrupt re-triggers Note, interrupt re-triggers after each clear and 0x3 is reported in Latched Register until T5. |

0x3 |

||

T4 (Int 3) |

0x0 |

0x0 |

Interrupt re-triggers Note, interrupt re-triggers after each clear until T7. |

0x2 |

||

T6 (Int 4) |

Interrupt Generated Read Latched Registers |

0xC |

Interrupt Generated Read Latched Registers |

0xC |

Interrupt Generated Read Latched Registers |

0xE |

T6 (Int 4) |

Write 0xC to Latched Register |

Write 0x4 to Latched Register |

Write 0xE to Latched Register |

|||

T6 (Int 4) |

0x0 |

Interrupt re-triggers Write 0x8 to Latched Register |

0x8 |

Interrupt re-triggers Note, interrupt re-triggers after each clear and 0xE is reported in Latched Register until T7. |

0xE |

|

T6 (Int 4) |

0x0 |

0x0 |

Interrupt re-triggers Note, interrupt re-triggers after each clear and 0xC is reported in Latched Register until T8. |

0xC |

||

T6 (Int 4) |

0x0 |

0x0 |

Interrupt re-triggers Note, interrupt re-triggers after each clear and 0x4 is reported in Latched Register always. |

0x4 |

||

REVISION HISTORY

Motherboard Manual - Status and Interrupts Revision History |

||

Revision |

Revision Date |

Description |

C |

2021-11-30 |

C08896; Transition manual to docbuilder format - no technical info change. |

DOCS.NAII REVISIONS

Revision Date |

Description |

- |

- |

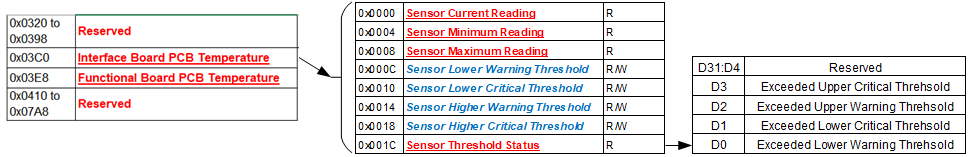

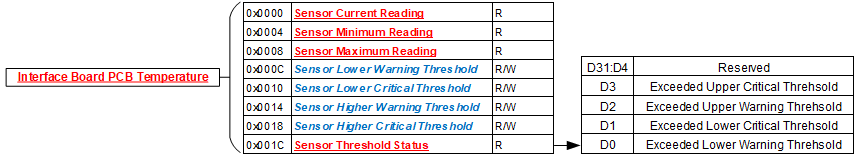

MODULE COMMON REGISTERS

Edit this on GitLab

The registers described in this document are common to all NAI Generation 5 modules.

Module Information Registers

The registers in this section provide module information such as firmware revisions, capabilities and unique serial number information.

FPGA Version Registers

The FPGA firmware version registers include registers that contain the Revision, Compile Timestamp, SerDes Revision, Template Revision and Zynq Block Revision information.

FPGA Revision

Function: |

FPGA firmware revision |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R |

Initialized Value: |

Value corresponding to the revision of the board’s FPGA |

Operational Settings: |

The upper 16-bits are the major revision and the lower 16-bits are the minor revision. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

Major Revision Number |

|||||||||||||||

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Minor Revision Number |

|||||||||||||||

FPGA Compile Timestamp

Function: |

Compile Timestamp for the FPGA firmware. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

N/A |

Read/Write: |

R |

Initialized Value: |

Value corresponding to the compile timestamp of the board’s FPGA |

Operational Settings: |

The 32-bit value represents the Day, Month, Year, Hour, Minutes and Seconds as formatted in the table: |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

day (5-bits) |

month (4-bits) |

year (6-bits) |

hr |

||||||||||||

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

hour (5-bits) |

minutes (6-bits) |

seconds (6-bits) |

|||||||||||||

FPGA SerDes Revision

Function: |

FPGA SerDes revision |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R |

Initialized Value: |

Value corresponding to the SerDes revision of the board’s FPGA |

Operational Settings: |

The upper 16-bits are the major revision, and the lower 16-bits are the minor revision. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

Major Revision Number |

|||||||||||||||

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Minor Revision Number |

|||||||||||||||

FPGA Template Revision

Function: |

FPGA Template revision |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R |

Initialized Value: |