DT5 Manual

- INTRODUCTION

- SPECIFICATIONS

- PRINCIPLE OF OPERATION

-

REGISTER DESCRIPTIONS

- Discrete Input/Switch Registers

- Discrete Input/Output Threshold Programming Registers

- Discrete Measurement Registers

- Discrete Input/Output Control Registers

- User Watchdog Time Programming Registers

- Module Common Registers

- Status and Interrupts

- User Watchdog Timer Fault Status

- Interrupt Vector and Steering

- ENHANCED FUNCTIONALITY

- FUNCTION REGISTER MAP

- Discrete Input/Output Measurement Registers

- APPENDIX: PIN-OUT DETAILS

- ENHANCED INPUT/OUTPUT FUNCTIONALITY CAPABILITY

- PRINCIPLE OF OPERATION

- REGISTER DESCRIPTIONS

- FUNCTION REGISTER MAP

- STATUS AND INTERRUPTS

- REVISION HISTORY

- USER WATCHDOG TIMER MODULE MANUAL

- REVISION HISTORY

- MODULE COMMON REGISTERS

- FUNCTION REGISTER MAP

- REVISION HISTORY

- NAI Cares

- Documentation

- FAQ

- Application Notes

- Calibration and Repairs

- Call Us

Edit this on GitLab

INTRODUCTION

NAI’s Discrete I/O Modules offer comprehensive interfacing solutions for embedded or test applications. The modules come in two versions: Standard Functionality (SF) modules and Enhanced Functionality (EF) modules, with both providing excellent programming flexibility, a broad operating range, and an innovative design that removes the need for pull-up resistors or mechanical jumpers. In addition, the EF Modules feature built-in operational functionality that can perform Pulse/Frequency Period Measurements of the incoming signal (Input) and/or Pulse/Frequency arbitrary signal generation (Output). These features make NAI’s Discrete I/O Modules suitable for a wide range of applications, including test and measurement, data acquisition, and control systems.

DT5 Overview

NAI’s DT5 Discrete/Switch module is a versatile electronic device designed for reliable and high-performance operation in harsh environments. This module features 16 independent, isolated, programmable channels that can be used for input voltage measurements (±80 V), or as a bidirectional current switch (up to 625 mA per channel). The module includes diode clamping on each channel, which provides protection against inductive loads.

The DT5 offers a wide range of features for accurate and reliable control and monitoring of switches and inductive loads. Key features of the module include:

Sixteen (16) channels available as inputs or outputs: The DT5 module features 16 independent, isolated, programmable channels that can be used as inputs or outputs, providing a high level of flexibility for a variety of applications.

Each channel programmable for input voltage or switch closure: Each channel of the DT5 module can be programmed as an input voltage or a switch closure, allowing for greater control and flexibility in system design.

Continuous background Built-in-Test (BIT): The DT5 module offers continuous background Built-in-Test (BIT) during normal operation, providing status for channel health and operation feedback. This ensures that the module operates reliably and accurately, with minimal errors or noise in the signal.

Ability to read switch I/O voltage and current: The DT5 module can read the voltage and current across the switch, allowing for precise monitoring and control of the circuit.

Ability to handle switch closure currents of up to 625 mA: The DT5 module can handle switch closure currents of up to 625 mA DC, providing high performance and reliability in demanding applications.

Programmable automatic switch overcurrent protection: The module features automatic switch overcurrent protection, which is programmable to a maximum of 625 mA, ensuring the safe and reliable operation of the circuit.

Open circuit detection: The DT5 module includes open circuit detection, which detects if a switch is open and provides an alert for further action.

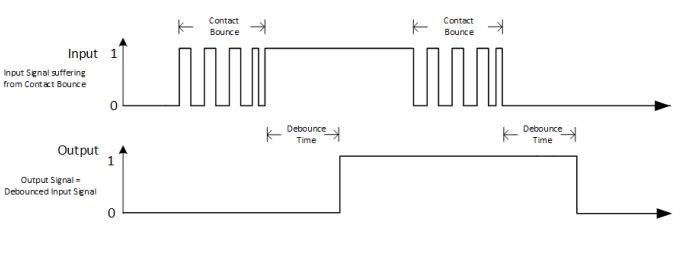

Clean, bounce-free switching: The DT5 module offers clean, bounce-free switching, ensuring that the module operates reliably and accurately, with minimal errors or noise in the signal.

Enhanced Functionality Features: In addition to offering the same functionality as the DT2 standard function (SF) module, the DT5 includes the following enhanced features:

-

Enhanced Input Mode - Pulse Measurements, Transition Timestamps, Transition Counters, Period Measurement, and Frequency Measurement.

-

Enhanced Output Mode - PWM Output and Pattern Generator Output; in bidirectional current switch mode, the enhanced features can be used to trigger switch opening or closure using pulse width, number of pulses, or pattern generation.

Overall, NAI’s DT5 Discrete/Switch Module is a highly versatile device that offers a wide range of features for accurate and reliable control and monitoring of switches and inductive loads. Its programmable channels, automatic protection features, and clean switching make it an excellent choice for a wide range of industrial and military applications.

SPECIFICATIONS

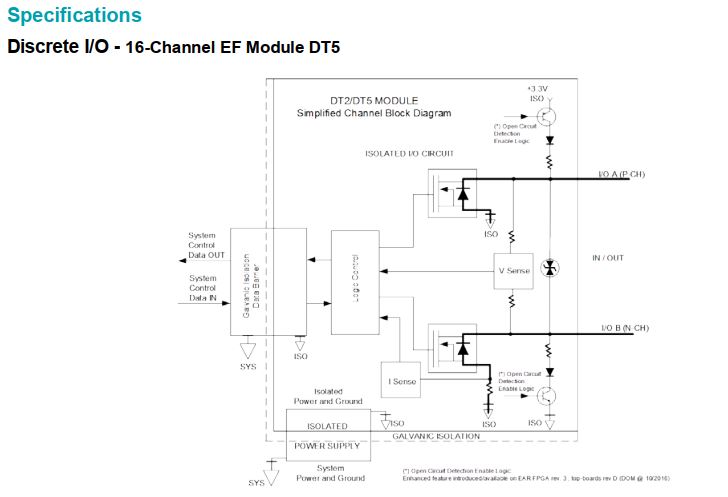

Discrete I/O - 16-Channel EF Module DT5

INPUT CHARACTERISTICS

Input Range: |

±80 V (peak) / ±60 V (typical) |

Input Pulse Detection: |

A pulse of 40µs min. width will be sensed and indicated by the appropriate Hi-Lo or Low-High Transition Interrupt. |

Input Impedance: |

2 MΩ / (200 kΩ if/when Open Circuit Detect Logic enabled) |

Switching Threshold: |

Levels are programmable from 0 to 80 Vrms with 10-bit resolution (0.98% FS) On/Off. |

Accuracy of Set Point: |

The greater of 5% signal value or 0.25 V. |

ON/OFF Differential |

|

0.5 V min. recommended. |

|

Debounce: |

Programmable per channel from 0 to 10µs x 232 (LSB= 10 μs; 32-bit resolution). |

Update Rate: |

Each channel is updated every 10 μs. |

Overvoltage Protection: |

Input clamped at ±80 VDC. |

Voltage Measurement: |

User can read output voltage of each channel (isolated 10-bit A/D) LSB=100mV; Accuracy: ±3 LSB’s (300 mV) over temperature. |

Additional Enhanced Input Mode Operation: |

Input with debounce filter (Mode 0), measure High Time (Mode 1), measure Low Time (Mode 2), time-stamp of all rising edges (Mode 3), time-stamp of all falling edges (Mode 4), time-stamp of all edges (Mode 5), count total number of rising (Mode 6), falling (Mode 7), all (Mode 8) edges, measure period from rising edge-to-rising edge (Mode 9),measure frequency (Mode 10). |

BIDIRECTIONAL SWITCH

Switch Formats: |

Isolated bidirectional (AC/DC) MOSFET switch |

Switch Current: |

0-625 mA per channel (load determined) / (±80 V peak) |

Switch Impedance Open: |

2 MΩ / (200 kΩ if/when Open Circuit Detect Logic enabled) |

Switch Impedance Closed: |

0.5 W typical, 1 W max. |

Current Measurement: |

User can read AC/DC current through switch, independently for each channel, LSB=3 mA; Accuracy: The greater of ±10% of Signal or ±20mA over temperature. |

Measurement Update Rate: |

Each channel is updated every 10 µs. |

Isolation: |

500 V (between channels and each channel to system GND). |

Power: |

5 VDC/0.98 A max. |

Weight: |

1.5 oz. (42 g) |

Additional Enhanced Output ModeOperation: |

PWM Continuous Output, PWM Burst (n-times), and Pattern Generator Output. |

Specifications are subject to change without notice.

PRINCIPLE OF OPERATION

DT5 provides 16 independent, isolated, programmable channels that either can be used for input voltage measurements (+/-60 V), or as a bidirectional current switch (up to 625 mA per channel). With the switch closed,both the current through the switch and the voltage across the switch can be monitored. These modules include diode clamping on each channel. Clamping is useful for inductive loads, such as relays and short circuit protection.

The DT5 Mode Select register provides 13 Mode settings. Each channel can be set to any of the different input or output modes. All settings provide BIT fault detection, which enables flagging of non-compliant outputs or inconsistent input readings between dual input measurements.

All 16 channels are galvanically isolated from each other and from system ground. Each channel’s two-wire connection can function as an isolated voltage input or as an isolated bidirectional switch. When programmed to function as a bidirectional switch, a channel can control valves mechanical relays, indicators, etc. without concern about grounding. This module provides an automatic background built-in-test (BIT) for each channel. The BIT functions are always enabled and continually check that each channel is functioning properly.

Standard input operation is used for voltage sensing and measures both AC and DC input voltages. When operating as a switch, measurements for both voltage across and current through the switch closure are available. Current and Voltage measurements are available as both instantaneous and averaged (RMS).

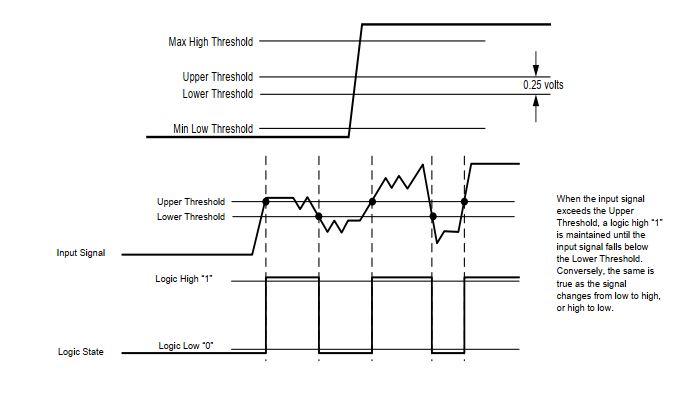

Four input voltage threshold levels (Maximum High, Upper, Lower, Minimum Low) are programmed to user defined high and low voltage levels. All four of the threshold levels must be set for each Input or Output channel. Threshold crossing may be programmed to generated interrupts on a change of state.

The module design utilizes state of the art galvanic isolation that is superior to alternatives such as optocoupler devices. The galvanic isolation eliminates typical optocoupler design concerns such as uncertain current transfer ratios, nonlinear transfer functions and temperature/lifetime degradation effects.

Input/Switch Interface

Each channel contains a both an isolated differential amplifier and a dual N-Channel MOSFET, configured as isolated Solid-State Relay (SSR). The SSR is energized, so both AC and DC current can flow through the channels I/O pins. The MOSFET presents a low ~.5 Ω on impedance. The module contains circuitry to measure the current through the SSR and the voltage present on the I/O pins.

Open Circuit Detection

Each of the 16 channels can be set to indicate an open circuit by setting the Open Circuit Detection register for the channel to 1. A voltage reading of 3.3 V indicates that the channel is open. Default (normal operation) is 0 V.Set the Maximum High Threshold register, for each channel, to this value to generate an interrupt using the Maximum High Threshold Interrupt Enable register.

|

Note

|

Added Enhanced Feature; introduced/available on EAR FPGA rev. 3; top-boards rev D (DOM @ 10/2016). |

Discrete I/O Threshold Programming

Four threshold levels: Max High Threshold, Upper Threshold, Lower Threshold, and Min Low Threshold offer maximum user flexibility. All four threshold levels must be programmed. For input or output, the threshold levels will define the logic states. For proper operation, the threshold values should be programmed such that:

Max High Threshold > Upper Threshold > Lower Threshold > Min Low Threshold

Program Upper and Lower Thresholds, keeping the 0.25 V min. differential in mind, and then add debounce time as required. When the input signal exceeds the Upper Threshold, a logic high 1 is maintained until the input signal falls below the Lower Threshold. Conversely, when the input signal falls below the Lower Threshold, a logic low 0 is maintained until the input signal rises above the Upper Threshold.

Debounce Programming

The Debounce register, when programmed for a non-zero value, is used with channels programmed as input to “filter” or “ignore” expected application spurious initial transitions. Once a signal level is a logic voltage level period longer than the Debounce Time (Logic High and Logic Low), a logic transition is validated. Signal pulse widths less than programmed Debounce Time are filtered. Once valid, the transition status register flag is set for the channel and the output logic changes state.

Automatic Background Built-In Test (BIT)/Diagnostic Capability

BIT is always enabled, and continually checks the health of each channel. This is accomplished by internal test circuitry that is incorporated into each 16-channel module. The test circuit is sequentially connected across each channel and checks that the commanded mode (input or switch closure) is correctly set, and depending upon the configuration, verifies that the channel data agrees with the test data or a possible fault is detected. Additionally, each output is continually checked for overcurrent, which is manually set for each channel. If the switch is open and current is any value other than 0 A, a BIT error will occur. If the switch is closed and voltage is any value other than 0 V, a BIT error will occur.

Status and Interrupts

The Discrete I/O Function Module provide registers that indicate faults or events. Refer to “Status and Interrupts Module Manual” for the Principle of Operation description.

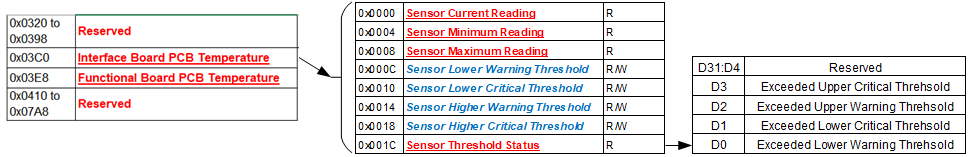

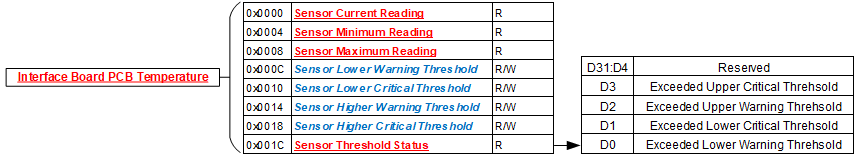

Module Common Registers

The Discrete I/O Function Module includes module common registers that provide access to module-level bare metal/FPGA revisions & compile times, unique serial number information, and temperature/voltage/current monitoring. Refer to “Module Common Registers Module Manual” for the detailed information.

REGISTER DESCRIPTIONS

The register descriptions provide the register name, Register Offset, Type, Data Range, Read or Write information, Initialized Value, a description of the function and, in most cases, a data table.

Discrete Input/Switch Registers

The Switch Control register commands the switch open or closed. the Read I/O register contains the discrete channel’s state (High (1) or Low (0)) as specified by the channel’s threshold configurations.

Switch Control

Function: Opens and closes the switch for each channel.

Type: unsigned binary word (32-bit)

Read/Write: R/W

Initialized Value: 0x0000 0000

Operational Settings: Write integer 0 for input; Write 1 for closed switch.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Open Circuit Detection

Function: Enables a 3.3V pull-up on the channel that may be used for open circuit detection.

Type: unsigned binary word (32-bit)

Read/Write: R/W

Initialized Value: 0x0000 0000

Operational Settings: Write integer 1 for open circuit detection. Default is 0, which does not provide open circuit detection. When an open circuit occurs, the voltage read on the channel will be pulled up to ~2.7V. Normal reading is 0.

An interrupt is generated for open circuit indication, by channel, via the Maximum High Threshold and Maximum High Threshold Interrupt Enable registers.

|

Note

|

Added Enhanced Feature; introduced/available on EAR FPGA rev. 3; top-boards rev D (DOM @ 10/2016). |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Switch State

Function: Reads whether the state of the switch is open or closed.

Type: unsigned binary word (32-bit)

Read/Write: R

Initialized Value: N/A

Operational Settings: N/A

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Read I/O

Function: Reads High 1 or Low 0 as defined by internal channel threshold values.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R

Initialized Value: N/A

Operational Settings: N/A

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Discrete Input/Output Threshold Programming Registers

Four threshold levels: Max High Threshold, Upper Threshold, Lower Threshold, and Min Low Threshold are programmable for each Discrete channel in the module.

Max High Threshold |

|||||||||||||||

Upper Threshold |

|||||||||||||||

Lower Threshold |

|||||||||||||||

Min Low Threshold |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Max High Threshold

Function: Sets the maximum high threshold value. Programmable per channel from -60 to 60 VDC, with binary 10-bit word resolution (LSB=100 mv).

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FDA8 to 0x0000 0258 (usable range)

Read/Write: R/W

Initialized Value: 0x64

Operational Settings: Assumes that the programmed level is the maximum voltage used to indicate a Max High Threshold. If a signal is greater than the Max High Threshold value, a flag is set in the Max High Threshold Status register. The Max High Threshold register may be used to monitor any type of high signal voltage condition or threshold such as a “Short to +V” as it applies to input measurement as well as contact sensing applications.

Upper Threshold

Function: Sets the upper threshold value. Programmable per channel from -60 to 60 VDC, with binary 10-bit word resolution (LSB=100 mv).

Type: signed binary word (32-bit)

Data Range: 0xFFFF FDA8 to 0x0000 0258 (usable range)

Read/Write: R/W

Initialized Value: 0x32

Operational Settings: A signal is considered logic High (1) when its value exceeds the Upper Threshold and does not consequently fall below the Upper Threshold in less than the programmed Debounce Time.

Lower Threshold

Function: Sets the lower threshold value. Programmable per channel from -60 to 60 VDC, with binary 10-bit word resolution (LSB=100 mv).

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FDA8 to 0x0000 0258 (usable range)

Read/Write: R/W

Initialized Value: 0x1E

Operational Settings: A signal is considered logic Low (0) when its value falls below the Lower Threshold and does not consequently rise above the Lower Threshold in less than the programmed Debounce Time.

Min Low Threshold

Function: Sets the minimum low threshold. Programmable per channel from -60 to 60 VDC, with binary 10-bit word resolution (LSB=100 mv).

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FDA8 to 0x0000 0258 (usable range)

Read/Write: R/W

Initialized Value: 0x0

Operational Settings: The programmed level is the voltage used to indicate a minimum low threshold. If a signal is less than the Min Low Threshold value, a flag is set in the Min Low Threshold Status register. The Min Low Threshold register may be used to monitor any type of low signal voltage condition or threshold such as a “Short to Ground” as it applies to input measurement as well as contact sensing applications.

Discrete Measurement Registers

The measured voltage and current applied at or across the P/N pins for each channel can be read from the Voltage Reading and Current Reading registers.

Voltage Reading (Sampled)

Function: Reads actual voltage at I/O pin per individual channel.

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FDA8 to 0x0000 0258 (usable range)

Read/Write: R

Initialized Value: N/A

Operational Settings: Value is a signed binary 32-bit word, where LSB = 100 mV. Data is read as 2’s complement number. For example, if output voltage word is 0x00F0 (240d), actual voltage is 24.0 V.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Voltage Reading (Averaged)

Function: Reads averaged value of the output voltage at I/O pin per individual channel.

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FDA8 to 0x0000 0258 (usable range)

Read/Write: R

Initialized Value: N/A

Operational Settings: Value is an unsigned binary 10-bit word, where LSB=100 mV. For example, if output voltage word is 0x00F0 (240d), actual voltage is 24.0 V.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Current Reading (Sampled)

Function: Reads current through the I/O pins per individual channel.

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FEC8 to 0x0000 0138

Read/Write: R

Initialized Value: Updated by module as per conditions

Operational Settings: Value is signed binary 32-bit word, where LSB=2 mA. Read as 2’s complement; Current source is positive, Current sink is negative. For example, if output current word is 0x0064 (100d), actual current is 200 mA.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Current Reading (Averaged)

Function: Reads averaged current through the I/O pins per individual channel.

Type: signed binary dword (32-bit)

Data Range: 0xFFFF FEC8 to 0x0000 0138

Read/Write: R

Initialized Value: N/A

Operational Settings: Value is signed binary 32-bit word, where LSB=2 mA. Read as 2’s complement; Current source is positive, Current sink is negative. For example, if output current word is 0x0064 (100d), actual current is 200 mA.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Discrete Input/Output Control Registers

Control of the Discrete switch channels include specifying the Debounce time for each input channel and resetting the switch channel on an overcurrent condition.

Debounce Time

Function: Sets the Debounce time (LSB= 10 μs; 32-bit resolution) for each channel.

Type: unsigned binary dword (32-bit)

Data Range: 0x0000 0000 to 0xFFFF FFFF

Read/Write: R/W

Initialized Value: 0 (no debounce/disabled)

Operational Settings: The Debounce Time register, when programmed for a non-zero value, is used with channels to “filter” or “ignore” expected application spurious initial transitions. Enter required Debounce Time into appropriate channel registers. LSB weight is 10 µs/bit (register may be programmed from 0x0000 0000 (debounce filter inactive) through a maximum of 0xFFFF FFFF (2^32 * 10µs) (full scale w/ 10 µs resolution). Once a signal level is a logic voltage level period longer than the debounce time (Logic High and Logic Low), a logic transition is validated. Signal pulse widths less than programmed Debounce Time are filtered. Once valid, the transition status register flag is set for the channel and the output logic changes state. Enter a value of 0000h to disable debounce filtering.

Overcurrent Value

Function: Sets the overcurrent value for each channel.

Type: signed binary dword (32-bit)

Data Range: 0x0000 0000 to 0x0000 0138

Read/Write: R/W

Initialized Value: 0x138

Operational Settings: LSB = 2 mA

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Overcurrent Reset

Function: Resets disabled channels in Overcurrent Latched Status register following an overcurrent condition as measured by the Current Reading register.

Type: unsigned binary dword (32-bit)

Data Range: 0x0000 0000 to 0x0000 0001

Read/Write: R/W

Initialized Value: 0x0

Operational Settings: 1 is written to reset disabled channels. Processor will write a 0 back to the Overcurrent Reset register when reset process is complete.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

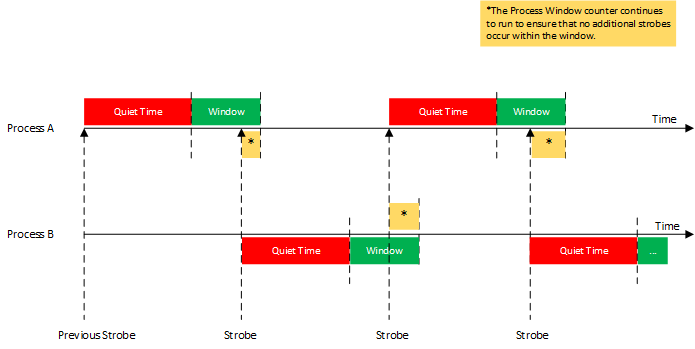

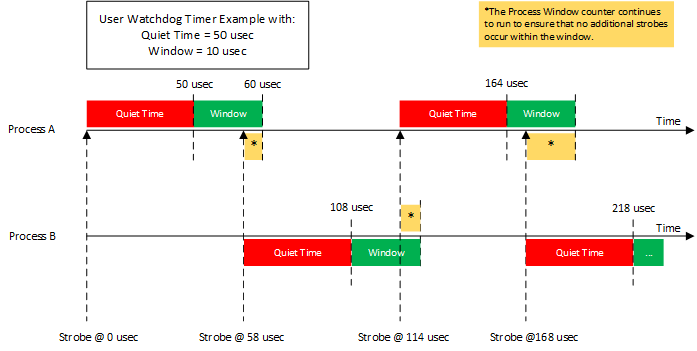

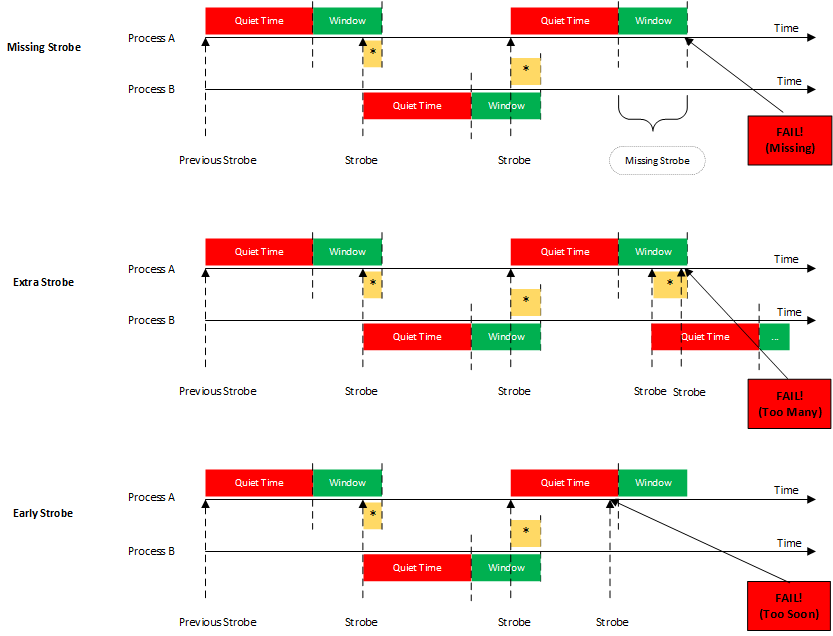

User Watchdog Time Programming Registers

Refer to “User Watchdog Timer Module Manual” for the register descriptions.

Module Common Registers

Refer to “Module Common Registers Module Manual” for the register descriptions.

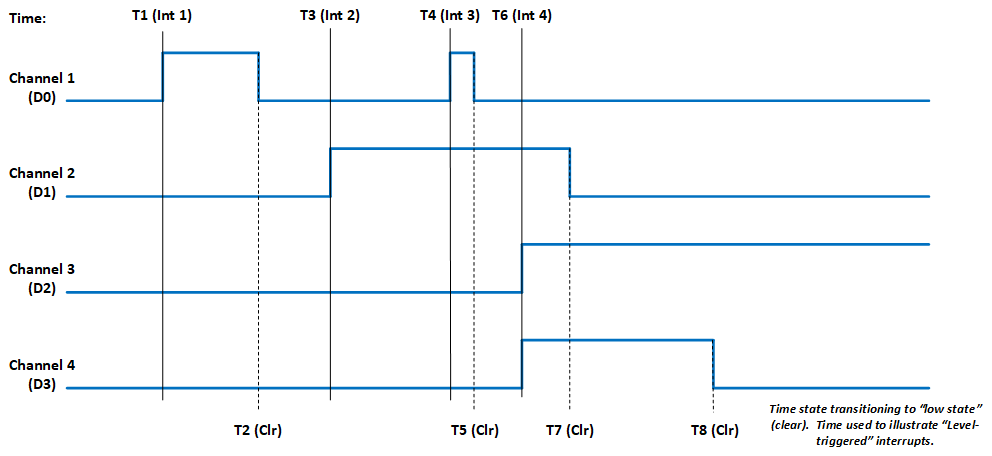

Status and Interrupts

The Discrete Module provides status registers for BIT, Low-to-High Transition, High-to-Low Transition, Overcurrent, Above Max High Threshold, Below Min Low Threshold, and Mid-Range.

BIT Status

There are four registers associated with the BIT Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

BIT Dynamic Status |

|||||||||||||||

BIT Latched Status |

|||||||||||||||

BIT Interrupt Enable |

|||||||||||||||

BIT Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s BIT error.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

|

Note

|

Faults are detected (associated channel(s) bit set to 1) within 10 ms. |

Overcurrent Status

There are four registers associated with the Overcurrent Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Overcurrent Dynamic Status |

|||||||||||||||

Overcurrent Latched Status |

|||||||||||||||

Overcurrent Interrupt Enable |

|||||||||||||||

Overcurrent Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s Overcurrent error.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

|

Note

|

Status is indicated (associated channel(s) bit set to 1), within 80 ms. |

|

Note

|

Channel(s) shut down by overcurrent sensed can be reset by writing to the Overcurrent Reset register |

Above Max High Threshold Status

There are four registers associated with the Above Max High Threshold Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt. Latched status is indicated (bit is set) within 500 µs. Write a 1 to clear status.

Above Max High Threshold Dynamic Status |

|||||||||||||||

Above Max High Threshold Latched Status |

|||||||||||||||

Above Max High Threshold Interrupt Enable |

|||||||||||||||

Above Max High Threshold Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s Above Max High Threshold event.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

Below Min Low Threshold Status

There are four registers associated with the Above Max High Threshold Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt. Latched status is indicated (bit is set) within 500 µs. Write a 1 to clear status.

Below Min Low Threshold Dynamic Status |

|||||||||||||||

Below Min Low Threshold Latched Status |

|||||||||||||||

Below Min Low Threshold Interrupt Enable |

|||||||||||||||

Below Min Low Threshold Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s Below Min Low Threshold event.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

Mid-Range Status

There are four registers associated with the Mid-Range Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt. Latched status is indicated (bit is set) within 500 µs. Write a 1 to clear status.

Mid-Range Dynamic Status |

|||||||||||||||

Mid-Range Latched Status |

|||||||||||||||

Mid-Range Interrupt Enable |

|||||||||||||||

Mid-Range Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s Mid-Range event.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

|

Note

|

Voltage level needs to be between the upper and lower thresholds for the debounce time for this status to assert. |

|

Note

|

In the event this status is asserted, the Input/Output state will hold its previous state. |

Low-to-High Transition Status

There are four registers associated with the High-to-Low Transition Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

Low-to-High Dynamic Status |

|||||||||||||||

Low-to-High Latched Status |

|||||||||||||||

Low-to-High Interrupt Enable |

|||||||||||||||

Low-to-High Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s Low-to-High Transition event.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

|

Note

|

Considered “momentary” during the actual event when detected. Programmable for level or edge sensing, status is indicated (associated channel(s) bit set to 1) within 20 µs. |

|

Note

|

Programmable for level or edge sensing, status is indicated (associated channel(s) bit set to 1) within 20 µs. |

|

Note

|

Transition status follows the value read by the Input/Output State register. |

High-to-Low Transition Status

There are four registers associated with the High-to-Low Transition Status: Dynamic, Latched, Interrupt Enable, and Set Edge/Level Interrupt.

High-to-Low Dynamic Status |

|||||||||||||||

High-to-Low Latched Status |

|||||||||||||||

High-to-Low Interrupt Enable |

|||||||||||||||

High-to-Low Set Edge/Level Interrupt |

|||||||||||||||

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

Ch16 |

Ch15 |

Ch14 |

Ch13 |

Ch12 |

Ch11 |

Ch10 |

Ch9 |

Ch8 |

Ch7 |

Ch6 |

Ch5 |

Ch4 |

Ch3 |

Ch2 |

Ch1 |

Function: Sets the corresponding bit associated with the channel’s High-to-Low Transition event.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x0000 FFFF

Read/Write: R (Dynamic), R/W (Latched, Interrupt Enable, Edge/Level Interrupt)

Initialized Value: 0

|

Note

|

Considered “momentary” during the actual event when detected. Programmable for level or edge sensing, status is indicated (associated channel(s) bit set to 1) within 20 µs. |

|

Note

|

Programmable for level or edge sensing, status is indicated (associated channel(s) bit set to 1) within 20 µs. |

|

Note

|

Transition status follows the value read by the Input/Output State register. |

User Watchdog Timer Fault Status

The Discrete Module provides registers that support User Watchdog Timer capability. Refer to “User Watchdog Timer Module Manual” for the User Watchdog Timer Fault Status register descriptions.

Interrupt Vector and Steering

Edit this on GitLab

When interrupts are enabled, the interrupt vector associated with the specific interrupt can be programmed (typically with a unique number/identifier) such that it can be utilized in the Interrupt Service Routine (ISR) to identify the type of interrupt. When an interrupt occurs, the contents of the Interrupt Vector registers is reported as part of the interrupt mechanism. In addition to specifying the interrupt vector, the interrupt can be directed (“steered”) to the native bus or to the application running on the onboard ARM processor.

|

Note

|

The Interrupt Vector and Interrupt Steering registers are mapped to the Motherboard Common Memory and these registers are associated with the Module Slot position (refer to Function Register Map). |

Interrupt Vector

Function: |

Set an identifier for the interrupt. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

0x0000 0000 to 0xFFFF FFFF |

Read/Write: |

R/W |

Initialized Value: |

0 |

Operational Settings: |

When an interrupt occurs, this value is reported as part of the interrupt mechanism. |

Interrupt Steering

Function: |

Sets where to direct the interrupt. |

Type: |

unsigned binary word (32-bit) |

Data Range: |

See table Read/Write: R/W |

Initialized Value: |

0 |

Operational Settings: |

When an interrupt occurs, the interrupt is sent as specified: |

Direct Interrupt to VME |

1 |

Direct Interrupt to ARM Processor (via SerDes) (Custom App on ARM or NAI Ethernet Listener App) |

2 |

Direct Interrupt to PCIe Bus |

5 |

Direct Interrupt to cPCI Bus |

6 |

ENHANCED FUNCTIONALITY

Input Modes

There are 10 Input modes. All input modes may be configured with debounce capability. Debounce capability allows configurable filtering of noisy signals and transients. Each channel may be set to an individual debounce time value. When a debounce time is set to a non-zero value, the signal reading after a transition must remain at the same level for the debounce interval before it is propagated through, otherwise it is rejected. All Input Modes (1-10) FIFO buffers are 1024 words deep.

Mode 0 - No Enhancement Mode: Behaves the same as a standard functionality only module.

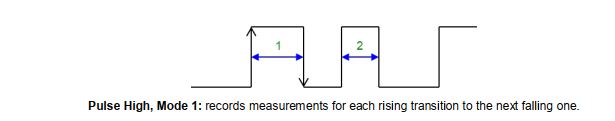

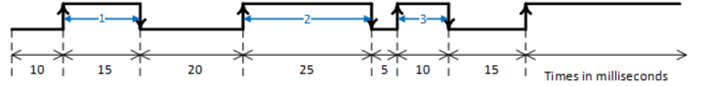

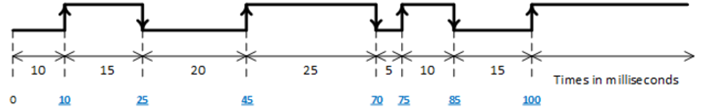

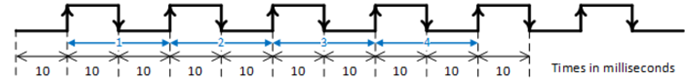

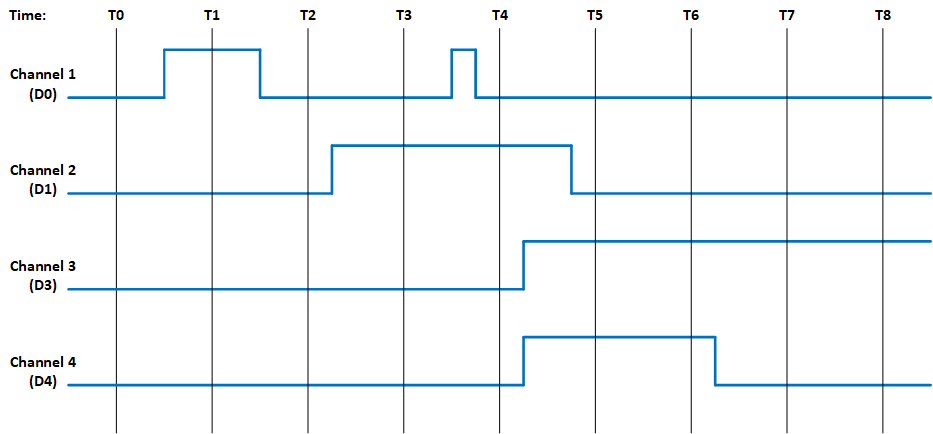

Mode 1 - High Time Pulse Measurement (FIFO Buffer): Timing measurements record the time interval (in 8 ns ticks) from a pair of transitions.

Pulse High, Mode 1: records measurements for each rising transition to the next falling one.

Mode 2 - Low Time Pulse Measurement (FIFO Buffer): Timing measurements record the time interval (in 8 ns ticks) from a pair of transitions.

Pulse Low, Mode 2: records the interval from each falling edge to the next rising edge.

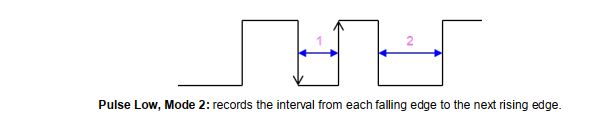

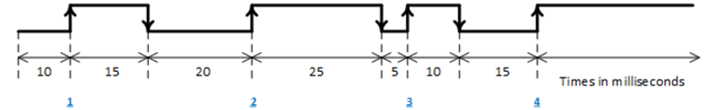

Mode 3 - Transition Timestamp of All Rising Edges (FIFO Buffer): Rising Edge time stamps from 125 MHz, 32-bit counter will be sequentially available and stored in the FIFO buffer.

|

Note

|

In this example, four counter values at the rising edge transitions are recorded to the FIFO: 0x344321, 0x344999, 0x345011, 0x345689, etc. |

Delta of 0x678 = 1656 counts, or 13.248 µs interval between pulses.

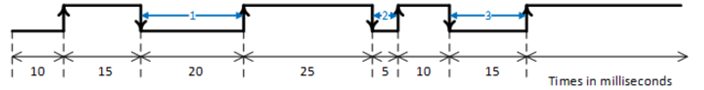

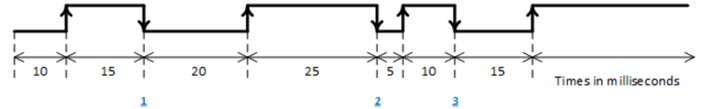

Mode 4 - Transition Timestamp of All Falling Edges (FIFO Buffer): Falling Edge time stamps from 125 MHz, 32-bit counter will be sequentially available and stored in the FIFO buffer.

Mode 5 - Transition Timestamp of All Edges (FIFO Buffer): Rising and Falling Edge time stamps from 125 MHz, 32-bit counter will be sequentially available and stored in the FIFO buffer.

|

Note

|

In this example, all edges time stamp. Four counter values at the transitions are recorded to the FIFO: 0x344321, 0x344999, 0x345011, 0x345689, etc. |

Delta of 0x33C = 828 counts, or 6.624 µs interval between pulses.

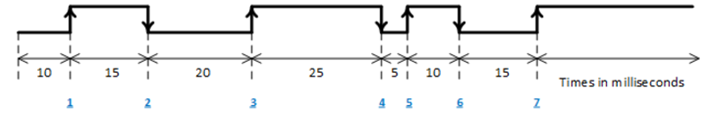

Mode 6 - Rising Edge Transition Counter: When selected, the rising edge count will be available from the count register at the FIFO read address. The counter is reset via user command.32-bit count range to 232.

Mode 7 - Falling Edge Transition Counter: When selected, falling edge count will be available from the count register at the FIFO read address. The counter is reset via user command. 32-bit count range to 232.

Mode 8 - Rising and Falling Edge Transition Counter: When selected, cumulative edge counts will be available from the count register at the FIFO read address. The counter is reset via user command. 32-bit count range to 232.

Mode 9 - Period Measurement: Timing measurements record the intervals from pulse-to-pulse in 8 ns ticks (delta timestamp).

|

Note

|

In Period Measurement mode, the same three pulse-to-pulse interval values as calculated in the timestamp measurement would be directly recorded to the FIFO. |

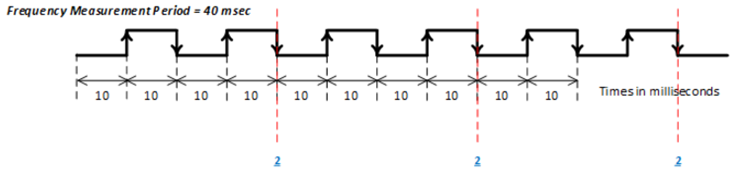

Mode 10 - Frequency Measurement: Enables frequency measurement, which will be available and stored in the FIFO buffer. Frequency measurement correlates to/utilizes a programmable time interval, which is programmed in the Period register. Direct readout of frequency is available when the interval is set to one second.

Output Modes

There are three Output modes, which include a standard output mode, two PWM outputs and a Pattern Generator Output mode.

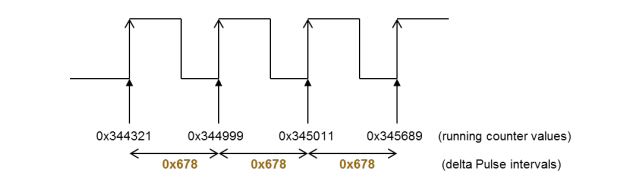

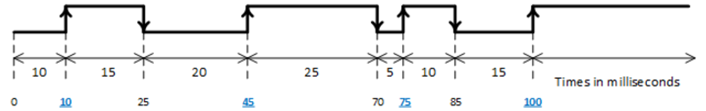

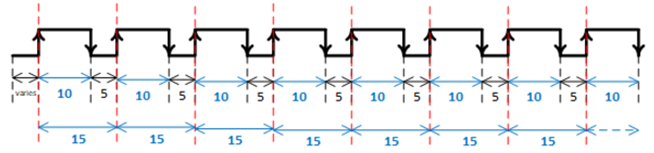

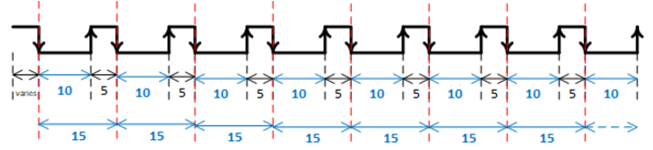

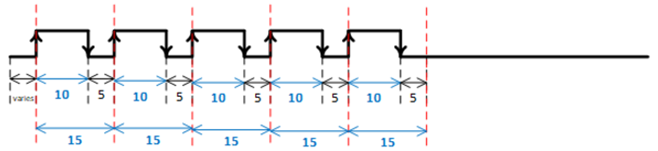

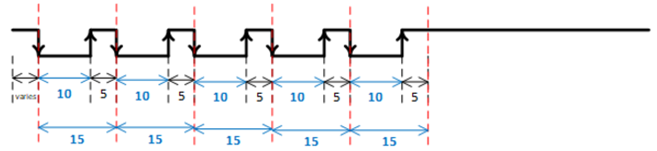

Mode 32 (0x20) - PWM Continuous Output Mode: In the sample shown below, each of the 24 channels has been set up with incrementing periods and pulse widths, running in continuous mode. Timing is asynchronous to each channel, but is very precise and with low jitter. In this mode, the configured PWM output is enabled and disabled with the Start Output/Measure Enable register.

Continuous Output Mode (Mode 32)

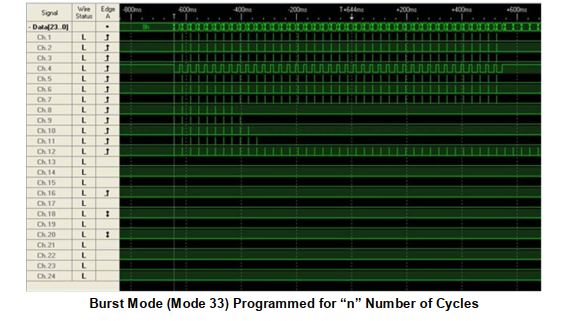

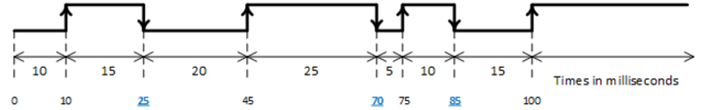

Mode 33 (0x21) - PWM Burst: Repeats the pulse based on programmed Period and Pulse Width “n” times as programmed in the Number of Cycles register.

Burst Mode (Mode 33) Programmed for “n” Number of Cycles

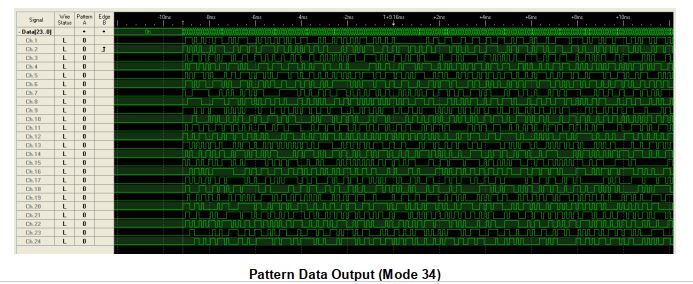

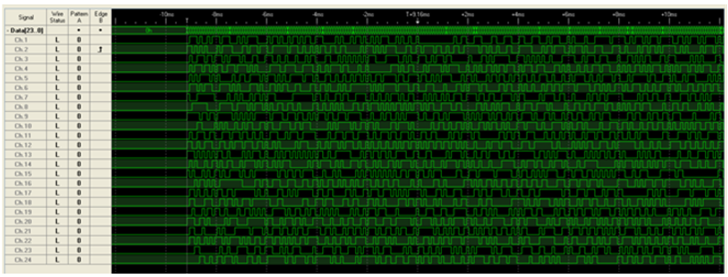

Mode 34 (0x22) - Pattern Generator Output: Outputs all mode selected channels based on the pattern programmed in the Pattern RAM register. The output rate is set in the Pattern RAM Period register. The output is a cyclic transmission of a 216 deep X 24 bit pattern array at configurable pattern intervals with 8 ns resolution. Pattern output may be stopped and resumed at the same point in the cycle. The following shows an arbitrary output of patterns as displayed on 24 channels of a logic analyzer. Each vertical column represents one 24-bit pattern of the 216 pattern array.

Pattern Data Output (Mode 34)

Mode Select

Function: This register provides selection of 13 different modes (0-10; 32,33,34). See the table that follows for a brief description of each mode.

Type: unsigned binary word (32-bit)

Data Range: 1 to 10; 32 to 34

Read/Write: R/W

Initialized Value: 0

Operational Settings: Modes 0 through 10; 32 through 34 are selectable for each channel. Writing a 0 will reset the Modes to their initialized state.

Mode # |

Hex |

Description |

1 |

0x0001 |

Measure “High” time: Write a 1 to the Start Output/Measure Enable register to enable measurement of the I/O state “High” time. It will not be measured if the bit is not set for that channel, i.e. 0. If a 1 is written to enable measurement on a channel while that channel’s I/O state is 1, then the internal counter will begin to count upon begin enabled. |

2 |

0x0002 |

Measure “Low” time: Write a 1 to the Start Output/Measure Enable register to enable measurement of the I/O state “Low time”. It will not be measured if the bit is not set for that channel. If a 1 is written to enable measurement on a channel while that channel’s I/O state is 0, then the internal counter will begin to count upon being enabled. |

3 |

0x0003 |

Time-stamp of all rising edges: Write a 1 to the Start Output/Measure Enable register and the timestamp counter will begin to count. A low-to-high transition on that channel will store the timestamp at the time of the transition in the FIFO. If that channel is then disabled by writing a 0, the timestamp counter will pause and any low-to-high transitions of the I/O state will not trigger FIFO storage. Write any value to the Reset Timer register to reset the timestamp counter. |

4 |

0x0004 |

Time-stamp of all falling edges: Write a 1 to the Start Output/Measure Enable register and the timestamp counter will begin to count. A high-to-low transition on that channel will store the timestamp at the time of the transition in the FIFO. If that channel is then disabled by writing a 0, the timestamp counter will pause and any high-to-low transitions of the I/O state will not trigger a FIFO storage. Write any value to the Reset Timer register to reset the timestamp counter. |

5 |

0x0005 |

Time-stamp of all edges: Write a 1 to the Start Output/Measure Enable register and the timestamp counter will begin to count. Any low-to-high or high-to-low transition on that channel will store the timestamp at the time of the transition in the FIFO. If that channel is then disabled by writing a 0, the timestamp counter will pause and any low-to-high or high-to-low transitions of the I/O state will not trigger FIFO storage. Write any value to the Reset Timer register to reset the timestamp counter. |

6 |

0x0006 |

Count total number of rising edges (until FIFO reset): Write a 1 to the Start Output/Measure Enable register to begin tracking any low-to-high transition of that channel’s I/O state will increment the counter by one. If a 0 is written in the register for that channel, the count will not increment on any transitions. Write any value to the Reset Timer register to reset the counter. |

7 |

0x0007 |

Count total number of falling edges (until FIFO reset): Write a 1 to the Start Output/Measure Enable register to begin tracking any high-to-low transition of that channel’s I/O state will increment the counter by one. If a 0 is written in the register for that channel, the count will not increment on any transitions. Write any value to the Reset Timer register to reset the counter. |

8 |

0x0008 |

Count total number of all edges (until FIFO reset): Write a 1 to the Start Output/Measure Enable register to begin tracking any low-to-high transition or high-to-low transition of that channel’s I/O state will increment the counter by one. If a 0 is written in the register for that channel, the count will not increment on any transitions. Write any value to the Reset Timer register to reset the counter. |

9 |

0x0009 |

Measure period from rising edge (L-H transition) to next rising edge: The first low-to-high transition of any enabled channel will start the counter. The next low-to-high transition will store the count in the FIFO, reset the counter, and begin the count again. This will repeat. After the waveform on the input has finished, write any value to the Reset Timer to reset it to zero. |

10 |

0x000A |

Measure frequency: The first low-to-high transition of any enabled channel will start the PWM Period counter. The counter will be incremented for every low-to-high transition that occurs within the defined period. Once the period counter reaches zero, the number of low-to-high transitions counted will be stored in FIFO and the process will restart. Write any value to the Reset Timer to reset it to zero. |

32 |

0x20 |

PWM - output continuously: Will continuously (repeat) the pulse based on programmed Period and Pulse Width registers. Write a 1 to output the continuous waveform programed in the Period and Pulse Width registers. Write a 0 to disable the output. |

33 |

0x21 |

PWM - output “n” times Will repeat the pulse based on programmed Period and Pulse Width “n” times as programmed in the Number of Cycles register. Write a 1 to output the number of pulses written in the Number of Cycles register with the period and pulse width written in the Period and Pulse Width registers. Once the programmed number of pulses that was written to the register has been outputted, a 0 will be written back to the register for the channel that was enabled (self-clearing). |

34 |

0x22 |

Output pattern data held in RAM: Outputs all mode selected channel(s) based on the pattern programmed in RAM. The output rate is set in the Pattern RAM Period register. The Pattern RAM Start Address register will determine where the pattern RAM output will begin when enabled. The Pattern RAM End Address register will determine where the pattern RAM output will end when enabled. After the pattern is outputted, it will loop back to the start address. Writing a 0x1 to the control register will loop the pattern continuously. While looping continuously, a 0x0 can be written to stop the output and bring the pattern back to the start address or a 0x5 can be written to pause the output wherever it may be in the pattern. Writing a 0x1 when the pattern is paused will resume the pattern at the same spot. Writing a 0x3 to the control register will burst the pattern from the start address to the end address for N number of times. N is determined by the value written in the Pattern RAM Period register. The Pattern RAM Period register determines how long the each address data will be output for. In other words, it is the time it takes for the output to change to the next address. |

Notes:

Mode 1 - 10 |

Input |

Mode 32 - 34 |

Output |

1 |

Mode(s) 1-10: FIFO storage occurs at 8 ns intervals (unless otherwise specified) |

2 |

Mode(s) 7- 9: Applies to measurement “count” edges - the “count” is provided/updated at 8ns intervals in the first element of the FIFO only (no FIFO 'storage” - first element is dynamically updated). |

3 |

Mode 10 (Measure frequency): In this mode, the captured FIFO data is essentially the number of transitions measured within a given user specified time interval (specified/programmed in the Pulse Width register). From this, the user calculates frequency by [FIFO Data (# of transitions) / Pulse Width], or, simply program the Pulse Width register to a time interval of 1 second, which then FIFO Data (# of transitions) directly correlates to measured frequency (Hz). |

Start Output/Measure Enable

Function:

Output Modes: When the Mode Select register is programmed for PWM output modes (Modes 32 & 33), the Start Output/Measure Enable register is used to start the channel outputs.

Input Modes: When the Mode Select register is programmed for PWM input modes (Modes 1-10), the Start Output/Measure Enable register is used to start measurement.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0xFFFF FFFF

Read/Write: R/W

Initialized Value: 0

Operational Settings: The channel(s) output is based on the pattern preset in the programmed pulse characteristic registers: Period, Pulse Width and Output Polarity. If the Mode Select register is set to Mode 33, the number of pulses is controlled by the Number of Cycles register.

Reset Timer

Function: Resets Timer to default value.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0xFFFF FFFF

Read/Write: W

Initialized Value: 0

Operational Settings: Writing any value to this register resets the Timer to default value.

|

Note

|

Resetting timers will also retrigger the FIFO store mechanism to trigger or restart the FIFO on the next valid low-to-high transition detected. |

FIFO Operations/Functions

There is an independent FIFO (1024 32-bit words deep) for each channel allocated for use when the Mode Select register is programmed for the appropriate mode (applies to Modes 1-10).

Read FIFO/Read Count

Function: Depends upon Mode Select register setting.

Read FIFO: Provides stored data dependent on the input channel(s) mode selected. Applicable to Modes 1 through 5, 9 and 10. See Mode Select register.

Read Count: Applicable to Modes 6, 7 and 8. See Mode Select register.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0xFFFF FFFF

Read/Write: R

Initialized Value: 0

Operational Settings: The available data in the FIFO buffer can be retrieved, one word at a time (32-bits), from the identified memory/register address.

|

Note

|

The Read FIFO and Read Count functions share a register. They are mutually exclusive in that depending upon the setting of the Mode Select register, either one or the other will become active. |

Read FIFO Count

Function: Reads the number of 32-bit words stored in FIFO for each channel.

Type: unsigned binary word (32-bit)

Data Range: Any value

Read/Write: R/W

Initialized Value: 0

Operational Settings: Mode Select register set for Modes 1-10.

Read FIFO Status

Function: Provides a real-time status of the following conditions:

-

FIFO empty

-

FIFO full

-

Almost Empty

-

Almost Full

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0000 to 0x4

Read/Write: R

Initialized Value: 0

Operational Settings: See table below.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

D |

Bit |

Description |

D0 |

Full |

D1 |

Almost Full |

D2 |

Almost Empty |

D3 |

Empty |

Reset FIFO

Function: Resets measurement FIFO (only) to zero. Applicable to Modes 1 through 5, 9 and 10. See Mode Select register.

Type: unsigned binary word (32-bit)

Read/Write: W

Initialized Value: 0

Operational Settings: The act of writing any value to this register will apply the reset.

PWM Operations/Functions

Unless otherwise specified, PWM operations and functions apply to channels when the Mode Select register is set for Modes 32 & 33.

Period

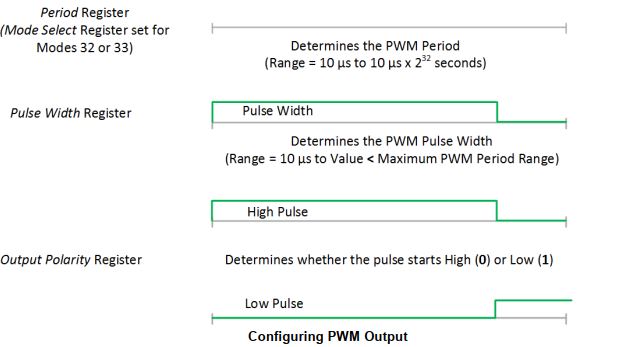

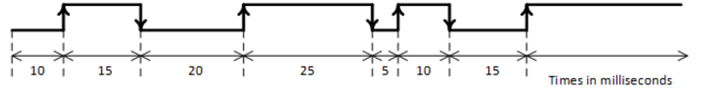

The Period register works in conjunction with the Pulse Width, Output Select, Number of Cycles and Start Output/Measure Enable registers to configure PWM output. See Configuring PWM Output figure below. It is also used for Period and Frequency measurement.

Configuring PWM Output

Function: When the Mode Select register is programmed for PWM output modes (Modes 32 & 33), the PWM Period is based on the programmed value set in this register.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0002 to 0xFFFF FFFF

Read/Write: R/W

Initialized Value: 0

Operational Settings: Mode Select register is set to Mode 32 or 33, the Period register is used to program the desired channel PWM output pulse period. Enter the desired PWM pulse period (LSB=@ 8 ns; valid entries are: 16 ns to 34.36 sec.).

|

Note

|

Programmed PWM Period must be greater than the value set in the Pulse Width register. |

Pulse Width

Function: When the Mode Select register is programmed for PWM output modes (Modes 32 & 33), the Pulse Width register is used to program the desired channel(s) PWM Pulse Width “ON” time. See Configuring PWM Output figure. When the Mode Select register is programmed for frequency measurement (Mode 10), the Pulse Width register is used to program the Timebase for the desired channel(s).

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0001 to 0xFFFF FFFE

Read/Write: R/W

Initialized Value: 0

Operational Settings:

Applied to Mode(s) 32 & 33: Enter the desired PWM Pulse Width (LSB=@ 8 ns; 10 µs to @ 10 µs to 10 µs x 232 sec). Used in conjunction with the Period register.

|

Note

|

Programmed PWM Pulse Width must be less than the value set in the Period register. |

Applied to Mode 10: For channel(s) with functions that rely on frequency measurement, the Pulse Width register is used to program the desired channel “Timebase” for the frequency measurement transition count period of time.

|

Note

|

There may be an initial “low” level output delay based on the Period time before the initial pulse is output. |

Number of Cycles

Function: When Mode Select register is programmed for Mode 33, the Number of Cycles register is used to program the number of times to repeat the pulse.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0001 to 0xFFFF FFFF

Read/Write: R/W

Initialized Value: 0

Operational Settings: Pulse is determined and used in conjunction with the Period and Pulse Width registers. Enter the desired Number of Cycles.

|

Note

|

If continuous pulse generation is desired, select Mode 32. |

Pattern Generator Operations/Functions

Applies to channels set for Output mode 34 on the Mode Select register. There is an allocated RAM data pattern 64K deep RAM location range, bit-mapped per channel that can be used for multichannel pulse pattern generation. Each channel, when programmed for Mode 34, is bit-mapped (LSB = Ch1) and when triggered (timers are reset), will sequentially output the programmed RAM pattern at the rate programmed in the Pattern RAM Period register.

Pattern RAM Period

Function: Programs the desired channel output pattern rate.

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0001 to 0xFFFF FFFF

Read/Write: R/W

Initialized Value: 0

Operational Settings: Enter the desired Pattern Generator RAM period (LSB=@ 10 ns).

Default: 0

Pattern RAM Start Address

Function: Programs the starting address for the Pattern Generator.

Type: unsigned binary word (32-bit)

Data Range: 0x40000 to 0x7FFFC

Read/Write: R/W

Initialized Value: 0

Operational Settings: Output rate is determined by the rate programmed in the Pattern RAM Period register. Write a 1 to start the RAM pattern output; write a 0 to stop the RAM pattern output.

Default: 0

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Pattern RAM End Address

Function: Programs the ending address for the Pattern Generator. There are 32K address locations from 0x40000 to 0x7FFFC.

Register Offset(s): 0x2018

Type: unsigned binary word (32-bit)

Data Range: 0x40000 to 0x7FFFC

Read/Write: R/W

Initialized Value: 0

Operational Settings: NA

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

D |

Pattern RAM Number of Cycles

Function: Program the number of times to repeat the pattern.

Register Offset(s): 0x2020

Type: unsigned binary word (32-bit)

Data Range: 0x0000 0001 to 0xFFFF FFFF

Read/Write: R/W

Initialized Value: 0

Operational Settings: Programmable from 1 to 232 cycles.

Pattern RAM Control

Function: Control the RAM data pattern.

Type: unsigned binary word (32-bit)

Data Range: N/A

Read/Write: W

Initialized Value: 0

Operational Settings: The Pattern RAM Start Address register determines where the pattern RAM output will begin when enabled. The Pattern RAM End Address register determines where the pattern RAM output will end when enabled. After the pattern at the pattern end address is outputted, it will loop back to the start address.

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0D |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

D |

D |

D |

D |

|

Note

|

Write the following values to the register to perform each function. |

Bit |

Function |

D0 |

Pattern Looping: This bit will enable or disable continuous pattern looping. Write 0x1 to enable and 0x0 to disable the pattern. |

D1 |

Burst Mode: Write 0x3 will burst the pattern from the start address to the end address for N number of times. N is determined by the value written in the Pattern RAM Number of Cycles register. |

D2 |

Pause: Write 0x5 to pause the pattern when enabled. |

D3 |

Rising Edge External Trigger Enable: Uses Channel 1 as the input. Write 0xA to enable pattern burst on a rising edge. |

D4 |

Falling Edge External Trigger Enable: Uses Channel 1 as the input. Write 0x12 to enable pattern burst on a falling edge. |

Output Polarity

Function: When the Mode Select register is programmed for PWM output modes (Modes 32 & 33), the Output Polarity programs the PWM Pulse Period to start either High (0) or Low (1).

Type: unsigned binary word (32-bit)

Read/Write: R/W

Initialized Value: 0

Operational Settings: Applies to Modes 32 and 33. The Output Polarity register is used to program the start “level” (or state) of the PWM Pulse Period. The default is ON (High), which is set when the PWM Polarity bit is 0. The PWM start level channel(s) output will be High for the initial start of the period. See Configuring PWM Output figure. The time is defined by the Period and Pulse Width registers. The remainder of the PWM Period time will be “low” defined by the [PWM Period - PWM Pulse Width]. If the PWM Polarity bit is set to 1, the PWM start level will be “low” for the programmed PWM Pulse Width and the remainder of the PWM Period time will be “high” defined by the [PWM Period - PWM Pulse Width]. Bit mapped per channel.

|

Note

|

There may be an initial “low” level output delay based on the Period time before the initial pulse is output. |

D31 |

D30 |

D29 |

D28 |

D27 |

D26 |

D25 |

D24 |

D23 |

D22 |

D21 |

D20 |

D19 |

D18 |

D17 |

D16 |

0 |

0 |

0 |

0 |

0 |

0 |

0 |

0 0 |

0 |

0 0 |

0 |

0 |

0 |

0 |

D15 |

D14 |

D13 |

D12 |

D11 |

D10 |

D9 |

D8 |

D7 |

D6 |

D5 |

D4 |

D3 |

D2 |

D1 |

D0 |

D |

D |

FUNCTION REGISTER MAP

Key:

Bold Italic = Configuration/Control

Bold Underline = State/Measurement/Status

*When an event is detected, the bit associated with the event is set in this register and will remain set until the user clears the event bit. Clearing the bit requires writing a 1 back to the specific bit that was set when read (i.e., write-1-to-clear, writing a “1” to a bit set to “1” will set the bit to “0).

Discrete Input/Switch Registers

0x1000 |

Switch Control |

R/W |

0x1004 |

Read I/O |

R |

0x1010 |

Switch State |

R |

0x100C |

Open Circuit Detection(*1) |

R/W |

(*1) Note: A. Open Circuit Detection enhanced feature; introduced/available on EAR FPGA rev. 3; top-boards rev D (DOM @ 10/2016)

Discrete Input/Output Threshold Programming Registers

0x2014 |

Max High Threshold Ch 1 |

R/W |

0x2094 |

Max High Threshold Ch 2 |

R/W |

0x2114 |

Max High Threshold Ch 3 |

R/W |

0x2194 |

Max High Threshold Ch 4 |

R/W |

0x2214 |

Max High Threshold Ch 5 |

R/W |

0x2294 |

Max High Threshold Ch 6 |

R/W |

0x2314 |

Max High Threshold Ch 7 |

R/W |

0x2394 |

Max High Threshold Ch 8 |

R/W |

0x2414 |

Max High Threshold Ch 9 |

R/W |

0x2494 |

Max High Threshold Ch 10 |

R/W |

0x2514 |

Max High Threshold Ch 11 |

R/W |

0x2594 |

Max High Threshold Ch 12 |

R/W |

0x2614 |

Max High Threshold Ch 13 |

R/W |

0x2694 |

Max High Threshold Ch 14 |

R/W |

0x2714 |

Max High Threshold Ch 15 |

R/W |

0x2794 |

Max High Threshold Ch 16 |

R/W |

0x2018 |

Upper Threshold Ch 1 |

R/W |

0x2098 |

Upper Threshold Ch 2 |

R/W |

0x2118 |

Upper Threshold Ch 3 |

R/W |

0x2198 |

Upper Threshold Ch 4 |

R/W |

0x2218 |

Upper Threshold Ch 5 |

R/W |

0x2298 |

Upper Threshold Ch 6 |

R/W |

0x2318 |

Upper Threshold Ch 7 |

R/W |

0x2398 |

Upper Threshold Ch 8 |

R/W |

0x2418 |

Upper Threshold Ch 9 |

R/W |

0x2498 |

Upper Threshold Ch 10 |

R/W |

0x2518 |

Upper Threshold Ch 11 |

R/W |

0x2598 |

Upper Threshold Ch 12 |

R/W |

0x2618 |

Upper Threshold Ch 13 |

R/W |

0x2698 |

Upper Threshold Ch 14 |

R/W |

0x2718 |

Upper Threshold Ch 15 |

R/W |

0x2798 |

Upper Threshold Ch 16 |

R/W |

0x201C |

Lower Threshold Ch 1 |

R/W |

0x209C |

Lower Threshold Ch 2 |

R/W |

0x211C |

Lower Threshold Ch 3 |

R/W |

0x219C |

Lower Threshold Ch 4 |

R/W |

0x221C |

Lower Threshold Ch 5 |

R/W |

0x229C |

Lower Threshold Ch 6 |

R/W |

0x231C |

Lower Threshold Ch 7 |

R/W |

0x239C |

Lower Threshold Ch 8 |

R/W |

0x241C |

Lower Threshold Ch 9 |

R/W |

0x249C |

Lower Threshold Ch 10 |

R/W |

0x251C |

Lower Threshold Ch 11 |

R/W |

0x259C |

Lower Threshold Ch 12 |

R/W |

0x261C |

Lower Threshold Ch 13 |

R/W |

0x269C |

Lower Threshold Ch 14 |

R/W |

0x271C |

Lower Threshold Ch 15 |

R/W |

0x279C |

Lower Threshold Ch 16 |

R/W |

0x2020 |

Min Low Threshold Ch 1 |

R/W |

0x20A0 |

Min Low Threshold Ch 2 |

R/W |

0x2120 |

Min Low Threshold Ch 3 |

R/W |

0x21A0 |

Min Low Threshold Ch 4 |

R/W |

0x2220 |

Min Low Threshold Ch 5 |

R/W |

0x22A0 |

Min Low Threshold Ch 6 |

R/W |

0x2320 |

Min Low Threshold Ch 7 |

R/W |

0x23A0 |

Min Low Threshold Ch 8 |

R/W |

0x2420 |

Min Low Threshold Ch 9 |

R/W |

0x24A0 |

Min Low Threshold Ch 10 |

R/W |

0x2520 |

Min Low Threshold Ch 11 |

R/W |

0x25A0 |

Min Low Threshold Ch 12 |

R/W |

0x2620 |

Min Low Threshold Ch 13 |

R/W |

0x26A0 |

Min Low Threshold Ch 14 |

R/W |

0x2720 |

Min Low Threshold Ch 15 |

R/W |

0x27A0 |

Min Low Threshold Ch 16 |

R/W |

Discrete Input/Output Measurement Registers

0x2000 |

Voltage Reading (Sampled) Ch 1 |

R |

0x2080 |

Voltage Reading (Sampled) Ch 2 |

R |

0x2100 |

Voltage Reading (Sampled) Ch 3 |

R |

0x2180 |

Voltage Reading (Sampled) Ch 4 |

R |

0x2200 |

Voltage Reading (Sampled) Ch 5 |

R |

0x2280 |

Voltage Reading (Sampled) Ch 6 |

R |

0x2300 |

Voltage Reading (Sampled) Ch 7 |

R |

0x2380 |

Voltage Reading (Sampled) Ch 8 |

R |

0x2400 |

Voltage Reading (Sampled) Ch 9 |

R |

0x2480 |

Voltage Reading (Sampled) Ch 10 |

R |

0x2500 |

Voltage Reading (Sampled) Ch 11 |

R |

0x2580 |

Voltage Reading (Sampled) Ch 12 |

R |

0x2600 |

Voltage Reading (Sampled) Ch 13 |

R |

0x2680 |

Voltage Reading (Sampled) Ch 14 |

R |

0x2700 |

Voltage Reading (Sampled) Ch 15 |

R |

0x2780 |

Voltage Reading (Sampled) Ch 16 |

R |

0x2004 |

Voltage Reading (Averaged) Ch 1 |

R |

0x2084 |

Voltage Reading (Averaged) Ch 2 |

R |

0x2104 |

Voltage Reading (Averaged) Ch 3 |

R |

0x2184 |

Voltage Reading (Averaged) Ch 4 |

R |

0x2204 |

Voltage Reading (Averaged) Ch 5 |

R |

0x2284 |

Voltage Reading (Averaged) Ch 6 |

R |

0x2304 |

Voltage Reading (Averaged) Ch 7 |

R |

0x2384 |

Voltage Reading (Averaged) Ch 8 |

R |

0x2404 |

Voltage Reading (Averaged) Ch 9 |

R |

0x2484 |

Voltage Reading (Averaged) Ch 10 |

R |

0x2504 |

Voltage Reading (Averaged) Ch 11 |

R |

0x2584 |

Voltage Reading (Averaged) Ch 12 |

R |

0x2604 |

Voltage Reading (Averaged) Ch 13 |

R |

0x2684 |